Select models built from 600D polyester or 900D Cordura-style fabric with a PU coating and taped seams at stress points; those materials typically weigh 300–700 g (10–25 oz) and tolerate regular gym and commute cycles without rapid abrasion. Prioritize units with YKK zippers, metal zipper pulls and reinforced stitching at strap anchors to avoid early failure.

Target capacities and measured specs: 16–20 L suits daily commuting (fits 13″–15″ laptops in a padded sleeve, approximate dimensions 45×30×15 cm / 18×12×6 in); 20–30 L covers day trips and heavier class loads; 30–35 L or a travel variant works for short overnight trips. Expect water-bottle pockets to hold 700–1,000 ml bottles; shoulder padding thickness of 10–20 mm improves load comfort for weights up to 8–10 kg (18–22 lb).

Feature checklist for purchase decisions: a lined laptop compartment, internal organizer panel for pens and phone, lockable main-zip option for travel, a ventilated shoe or wet pocket for gym use, and a reinforced base fabric (double-layer or TPE-coated panel). Price bands commonly range $30–$90 USD depending on capacity and materials; models under $40 often omit reinforced bases and premium zippers.

Use-case recommendations: for campus and office choose 18–22 L with a padded sleeve and organizer; for gym-focused carry pick 15–18 L with a ventilated compartment; for short travel select 25–30 L with a zippered internal organizer and trolley pass-through. Maintenance: spot-clean with mild detergent, avoid tumble drying, and air-dry in shade; treat PU-coated bases with a silicone-based water repellent once per season to maintain surface resistance. Warranty periods normally run 12 months; check seller return terms before purchase.

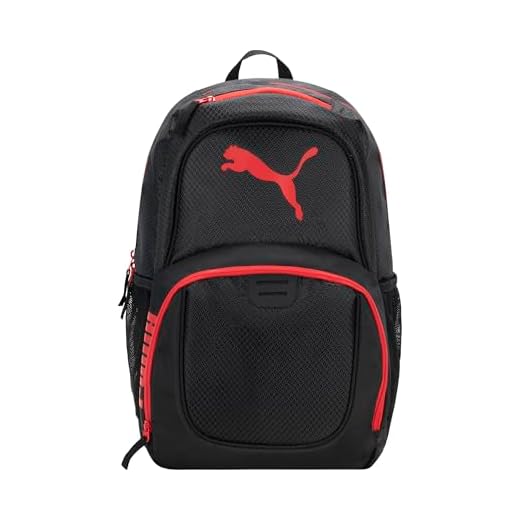

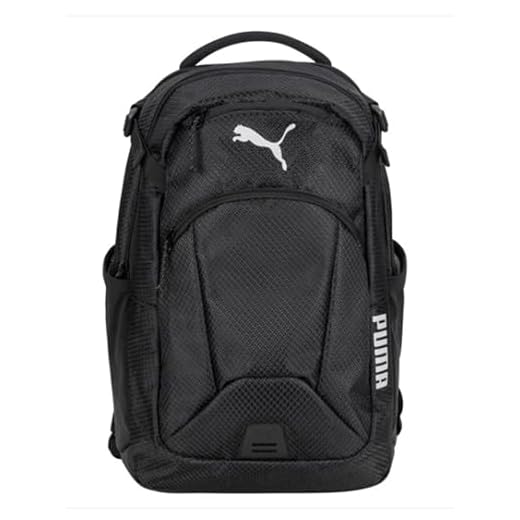

Verdict: practical recommendation for the sportswear label’s daypacks

Recommendation: pick mid-range models with 600D polyester or higher, YKK or comparable zippers, a padded laptop sleeve sized for 13–15″ or 15–17″ devices, and a reinforced base; expect 2–5 years of normal daily use under typical commute and school loads.

Construction specifics: preferred fabric weight 600–1000D for abrasion resistance, PU coating for water resistance (not waterproof), double-stitched shoulder seams, and foam back panels roughly 8–12 mm thick for comfort. Typical empty weight falls between 400 g (small daypacks) and 900 g (larger, feature-rich models); standard capacity ranges 15–35 L.

Use-case guidance: students and commuters benefit from 20–30 L options with a dedicated laptop compartment and organizer pockets; gym users can choose 15–20 L simple designs with a shoe pocket; short-trip travellers should look for 30–35 L versions with a sternum strap or removable hip strap for better load distribution. Models lacking hip belts perform poorly under loads above 8–10 kg.

What to check before purchase

Zipper quality: YKK or metal sliders last longer than stamped plastic. Seams: inspect double stitching and bartacks at stress points. Padding: verify lumbar foam and strap width (25–50 mm) for extended wear. Water resistance: PU-coated fabric and taped seams improve protection; for heavy rain, add a rain cover.

Care tips and common weaknesses

Maintenance: spot-clean with mild detergent, avoid machine washing to preserve foam and coatings, reapply DWR spray annually for better repellency. Known limitations: entry-level units often skimp on internal organization and hardware robustness; prolonged exposure to heavy rain will leak through zippers and seams; warranty terms typically span 1–2 years depending on seller.

Which materials hold up under daily school or commute use?

Prefer packs made from 600–1000 denier (D) polyester or nylon with a PU or TPU coating and a reinforced base for reliable daily wear.

600D polyester: widely used for school bags because it balances abrasion resistance, weight and cost. Typical 600D fabric resists scuffs from lockers and bike straps and performs well through roughly 20,000+ Martindale abrasion cycles in common constructions; expect moderate water resistance when factory-treated with DWR plus a light PU coating.

1000D ballistic nylon / Cordura (1000–1680D): heavier, much higher abrasion resistance (commonly 50,000+ Martindale cycles for commercial-grade weaves). Use for bottoms, side panels and high-wear zones if you carry laptops, textbooks or tools frequently–adds weight but extends service life substantially.

420D and ripstop nylons: lighter than 600D yet tougher than 210–300D textiles; a ripstop weave prevents small tears from propagating. Good for commuter packs aiming to save weight while keeping reasonable durability when paired with a DWR finish and reinforced stress points.

Coatings and water management: PU and TPU coatings improve water resistance without the stiffness of PVC; look for DWR plus a hydrostatic head rating where available–~1,000 mm repels light rain, ~3,000 mm stands up to heavy showers. Fully waterproof performance requires taped or welded seams and waterproof zippers, otherwise expect water resistance only.

Hardware and construction to check: YKK or equivalent zippers (coil #5 or molded #8 for heavier loads); bartack and box-x reinforcements at strap anchors; double-stitched main seams; foam shoulder straps with medium density (roughly 25–35 kg/m³) and 10–15 mm of padding for comfort with school loads; base panel reinforced with 1000D fabric or TPU-coated material.

Materials to avoid for daily commuting: very thin polyester/nylon (150–210D) without reinforcement, PVC-coated fabrics that crack in cold or with age, and flimsy faux-leather trims that delaminate at seams. Weak zipper brands and single-stitch strap attachments are the usual failure points.

Quick selection checklist: choose 600–1000D main body or 420D ripstop for lighter packs; 1000–1680D or Cordura for the base and wear areas; PU/TPU coating plus DWR for weather resistance; YKK zippers and bartack/box-x reinforcements for longevity.

Comfort on long walks and heavy loads

Select models from the sports label with contoured S‑shaped shoulder straps (12–20 mm closed‑cell foam), a ventilated back panel (15–25 mm foam with air channels), an adjustable sternum strap and a removable or padded hip belt for loads above 8 kg.

Key specifications to check

Shoulder strap width: ≥45 mm for loads >8 kg; wider straps reduce pressure points and shoulder fatigue.

Padding thickness: 12–20 mm on shoulders, 15–25 mm on back panel. Denser foam (higher ILD) holds shape better under prolonged compression.

Hip belt: recommendable for carried weight >8 kg; a padded belt transfers 60–80% of the load to hips, lowering shoulder strain.

Sternum strap: adjustable height and quick‑release help stabilize load and prevent strap slip during long walks.

Compression straps and internal organizers: keep heavy items close to the spine to maintain center of gravity and reduce sway.

| Load (kg) | Feature set | Expected comfort for 2–4 hour walk |

|---|---|---|

| 0–5 | Light day model, thin padding, minimal hip support | Very comfortable (4–5/5) |

| 5–8 | Moderate padding, ventilated back, adjustable straps | Comfortable (3–4/5) |

| 8–12 | Padded shoulders, hip belt recommended, reinforced back | Good if hip belt used (3–4/5) |

| 12–15 | Sturdy carry system, wide straps, firm hip belt, internal frame advised | Moderate comfort; performance depends on fit (2–3/5) |

| >15 | Internal frame or dedicated trekking rucksack required | Poor with street models; not recommended |

Adjustment and packing technique

Load heavy items closest to the spine and centered; use compression straps to prevent shifting. Tighten hip belt first so 60–80% of weight sits on hips, then position shoulder straps to eliminate gap between shoulders and pack, and finally clip the sternum strap at mid‑chest for stability. Walk for 10 minutes and fine‑tune strap tension to avoid hotspots.

Laptop and electronics protection in this label’s daypacks during transit

Use models that include a suspended, padded laptop sleeve with 10–15 mm closed-cell foam and a secure strap – that configuration provides reliable shock isolation for daily commuting and carry-on travel.

- Padding specs: look for foam density ≥30 kg/m³ or EVA inserts; thickness 10–15 mm at the base and 8–12 mm on the sides minimizes impact transfer.

- Suspended sleeve: a sleeve that floats 20–30 mm above the pack floor prevents direct impact when the bag is set down; sleeves sewn into the back panel with a soft lining reduce abrasion.

- Internal layout: separate compartment for a charger and a tablet keeps rigid devices from contacting one another; zippered mesh pockets stop cables from sliding to corners.

- Closure and zippers: YKK-style zippers and flap-protected openings reduce snag and water ingress; a clamshell opening lets the pack lay flat for easier packing and less stress on electronics.

- Edge and corner reinforcement: reinforced seams and taped internal corners limit compression at the weakest contact points during drops or crowding in luggage.

- Weather resistance: DWR-treated fabric and taped seams lower the risk of moisture damage; if transits include heavy rain, add a rain cover or place devices in a waterproof sleeve.

Quick in-store checks before purchase

- Place your laptop inside the sleeve, fasten the retention strap, then bend and compress the pack lightly – the device should not contact hard seams or zipper hardware.

- Measure internal sleeve dimensions and compare with laptop width/height/depth; allow 10–15 mm clearance on each side for a slim protective case.

- Press the foam to confirm quick rebound (memory foam that stays indented is inferior for impact absorption).

Practical protection upgrades and packing tips

- For air travel or checked luggage use a dedicated hard case or a high-protection roller bag – see best luggage ever barracuda for options that outperform soft carry items.

- When multitasking (gym to office) replace thin internal dividers with a padded sleeve and keep chargers in a small organizer rather than loose in the main compartment; for gym-focused days consider a duffel and reserve the daypack for electronics – see best duffel bag for gym.

- Add a slim, certified sleeve (impact-rated or TSA-friendly) if the built-in padding is under 10 mm or lacks suspension.

If frequent rough handling is expected, choose a carry solution with separate rigid luggage or a purpose-built tech case rather than relying solely on a soft daypack’s internal padding.

Water resistance for rainy commutes and outdoor use

Recommendation: For light urban showers and daily commutes, this brand’s sport packs with DWR-treated polyester typically provide sufficient water repellence; for prolonged exposure, heavy downpours or wilderness treks, add a dedicated rain cover or use internal waterproof pouches for electronics and documents.

Materials and measurable performance

Common constructions: 600D polyester, 300D polyester and 420D nylon with a DWR finish or a thin PU coating. Expected performance ranges: uncoated fabric gives minimal resistance; DWR-treated surfaces bead water but do not prevent soak-through under sustained rain. Hydrostatic head guidance: 1,000–2,000 mm = light rain resistance; 2,000–5,000 mm = moderate rain; 5,000+ mm = strong resistance for extended exposure. Typical sport-lifestyle models fall under the 1,000–3,000 mm equivalent when factoring fabric and factory finishes. Seam treatment and zipper type matter more than fabric alone: taped seams and waterproof zippers block ingress; standard stitched seams and regular zips allow seepage even if outer fabric repels water.

Practical checks and field recommendations

Quick in-store checks: pour a small cup (≈100–200 ml) of water on the exterior and inspect interior after 30–60 seconds; look for beading versus immediate wetting. Review labels for “taped seams”, “waterproof zippers” or a listed hydrostatic head value. For everyday protection carry a pack-sized rain cover (20–25L, 25–35L, 35–45L sizing common) with at least 5,000 mm rating, or keep valuables inside a roll-top dry bag or an IP-rated pouch. Maintenance: renew DWR with a wash-in or spray treatment every 6–12 months or after ~10 washes; avoid hot tumble drying and use gentle detergent. For laptop security, place the device into a padded sleeve inside the dry pouch rather than relying on the main compartment alone.

Storage and organization features for everyday items in the brand’s daypacks

Opt for a model that combines a padded laptop sleeve (fits up to 15-inch laptops, roughly 38 × 26 cm), an internal organiser panel with at least three pockets for phone, pens and a power bank, a zippered valuables pocket and dual external stretch side pockets for bottles.

Volume guidance for daily carry: 12–15 L handles wallet, phone, compact tablet and a small water bottle; 18–22 L accommodates a 13–15″ laptop plus charger, lunchbox and medium bottle; 25–30 L provides room for laptop, gym shoes, change of clothes and a larger bottle.

Common compartment layout: a wide-mouth main compartment with a mesh zip pocket for cables (approx 18 × 12 cm), a front organiser panel with pen loops and card slots, a fleece-lined sunglasses pocket (~12 × 7 cm), and a small zippered internal stash for keys or coins. Look for elastic cable loops or a sewn-in cable channel if you carry multiple chargers.

Quick-access and security options to seek: lockable main-zip sliders, a hidden rear pocket behind the back panel for passport or phone, and a front top pocket for transit cards. Some models include a detachable key clip or a low-profile zippered pocket that sits against the wearer’s back.

Select features based on typical daily load: if you commute with multiple accessories choose an organiser panel and dedicated cable mesh pockets; if you combine office and gym use prioritize a 25 L+ model with a separate lower compartment or roomy main bay; if minimal carry is preferred pick a 12–15 L daypack with a single organiser panel and one side bottle pocket. Check product specs for pocket dimensions and sleeve padding thickness (10–12 mm foam recommended for routine protection of electronics).

Warranty reliability and repair/return process

Use the manufacturer’s standard two-year limited warranty for manufacturing defects: submit order number, product SKU, clear photos of the fault and the original proof of purchase as soon as the defect is discovered.

Coverage and exclusions

Typical coverage: defects in materials and workmanship (seams splitting at stitch lines, delaminating panels, hardware failure attributable to manufacturing). Typical exclusions: normal abrasion, cosmetic scuffs, dye transfer, cuts or punctures from sharp objects, damage from misuse or improper cleaning, exposure to saltwater or chemical cleaners, and modifications or removal of internal labels. Retailer return windows (usually 14–30 days) handle unwanted items; warranty claims handle functional defects reported during the warranty period.

Step-by-step claims and repair workflow

Step 1 – Evidence: photograph the whole product, close-ups of the defect, the product tag/SKU, and the purchase receipt or order confirmation. File names should include order number and date.

Step 2 – Retail return vs warranty claim: if within the retailer’s return window, request refund or exchange through the seller first. If outside that window but within the warranty period, proceed to the manufacturer’s support channel.

Step 3 – Contact support: use the brand’s official support portal or email support; include order number, SKU, purchase date, short description of the fault, and the photos. State preferred resolution (repair, replacement, or refund) and shipping address.

Step 4 – Shipping and assessment: follow instructions from support for shipping label and packaging. Typical initial response: 3–10 business days; assessment and repair/replacement turnaround: commonly 2–6 weeks depending on parts and regional logistics.

Step 5 – Outcomes and costs: validated warranty claims normally receive repair at no charge, replacement, or refund. If claim denied or product outside warranty, request a paid repair quote or return shipping options. Keep all tracking numbers and case IDs.

Step 6 – Aftercare: keep receipts for any paid repairs and request written confirmation of work performed; retain the repaired item’s documentation for future reference.

Sample claim message: “Order #: [number]. SKU: [code]. Purchase date: [dd/mm/yyyy]. Fault: [brief description]. Photos attached: overall, close-up, tag. Preferred resolution: repair or replacement.”

For an unrelated hardware reference see are smeg fridge freezer doors removable.