Materials: Siser EasyWeed HTV (or similar), cotton/polyester fabric paints (e.g., Pebeo Setacolor), textile medium for acrylics, polyester thread size 40, heavy-duty needle 90/14 for canvas or 100/16 for Cordura, YKK zippers (#5 for daily use, #10 for heavy loads), brass grommets 8 mm (5/16″), snap studs or rivets (6 mm post), Gear Aid Seam Grip for reinforcement, freezer paper for templates, and a weeding hook. For tools use a Cricut Maker or Silhouette Cameo, a heat press or household iron (cotton setting), a zipper foot, and a small grommet press or setter.

Preparation and measurement: Wash the bag fabric on a gentle cycle and air-dry to remove factory coatings; measure panels precisely with a cloth tape, adding 3–4 mm allowance around patches or transfers. For logo sizes use: 6–8 cm high for shoulder straps, 8–12 cm for front pocket, and up to 20 cm for full-front panels. Create vector artwork at 300 DPI, mirror HTV designs before cutting, and use 60–120° blade settings depending on material (refer to cutter manual).

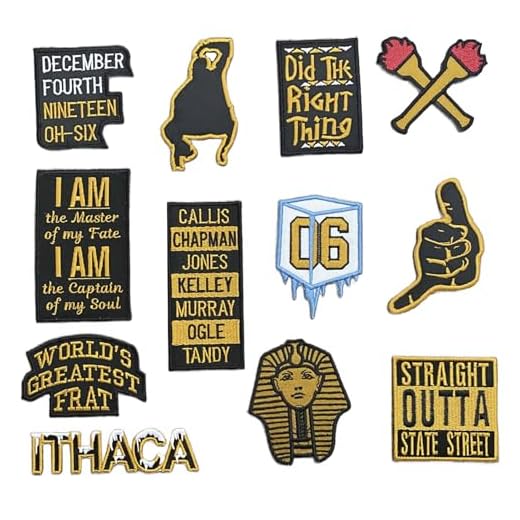

Application technique: Cut HTV and weed excess, preheat the target area 2–4 seconds to remove wrinkles, press HTV at 160°C (320°F) for 12–15 s with medium pressure for 10×10 cm pieces (scale time by area: +5 s per additional 50 cm²). For household irons: press firmly 20–30 s per zone, avoid sliding. Use cold-peel HTV for intricate vinyls or warm-peel as specified by the brand. For embroidered or sewn patches, baste with temporary adhesive, stitch 3–5 mm from the edge using a bar-tack (6–8 back-and-forth passes) at stress points, and finish with a zigzag 2.5 mm stitch for raw-edge patches.

Paints, sealing and care: For hand-painted graphics mix textile medium with acrylics 1:1, apply two thin coats, air-dry 24 hours, then heat-set by ironing on reverse at 150°C for 3 minutes or follow paint maker instructions. Seal seams and zipper repairs with a 2 mm bead of Seam Grip; cure 24–48 hours. Machine wash inside out on cold, gentle cycle; line-dry. Limit added weight from external attachments to ~500 g per reinforced zone to avoid strap deformation.

Quick alternatives: Use iron-on embroidered patches for fast changes (attach with HTV backing + a 4–6 mm stitched perimeter), stick-on vinyl decals for short-term looks, or riveted metal plates for industrial style–drill pilot holes, insert 8 mm grommets, and set with a hand press to prevent fabric tearing.

Place patches and pins away from seams, zippers and load-bearing anchors

Place patches and pins on flat panels with a minimum clearance of 1 in (2.5 cm) from any seam or zipper tooth and 1.5–2 in (4–5 cm) from strap anchors and bottom corners.

Safe-zone measurements and preferred locations

Front panel center: position large patches within a 10×10 cm square centered horizontally and 6–8 cm below the top handle or top seam. Side pockets and gussets: avoid entirely for sewn or heavy metal pins. Flap pockets and roll-tops: keep decorative elements at least 1 cm from the flap edge and 2 cm from the closure. Small pins (≤25 mm): can sit 1 in (2.5 cm) from seams; cluster spacing 15–20 mm between pin centers to prevent fabric puckering.

Reinforcement, fastening and testing

Thin nylon/nylon-ripstop: apply a circular fusible interfacing patch 3–4 cm larger than the attachment area on the inside before fixing. Thick cotton or heavy synthetic: use a 3–4 cm felt or leather washer behind metal pin backs. For enamel pins use metal locking clutches plus a 10 mm nylon washer on the inside; for large sew-on patches use a double row of stitches 3–4 mm from the patch edge with polyester thread and 2.5–3 mm machine stitch length. Iron-on transfers require a flat panel of at least 10×10 cm and 15–20 seconds of firm pressure at the manufacturer’s temperature–apply interfacing on the reverse for lightweight fabric.

Mark placement with chalk or a removable fabric marker, temporarily secure with safety pins or tape, then perform a pull test: apply 2–3 kg force perpendicular to the fabric for 10 seconds; if the fabric deforms more than 1 cm or stitches pull, add a reinforcing washer or move the item at least 2 cm inward from the stress point.

Attach embroidered and iron-on patches: heat settings, pressure and stitch reinforcement

Set a heat press to 320°F (160°C) at 40–60 psi for standard adhesive-backed embroidered patches; cover with a Teflon sheet or thin cotton, press 12–15 seconds, let cool 30–60 seconds before testing the bond.

Temperature, time and pressure by substrate

Poly/cotton blends: 305°F (150°C), 30–40 psi, 10–12 seconds. Pure polyester or heat-sensitive synthetics: 295°F (145°C), 20–30 psi, 8–10 seconds; always use a pressing cloth. Heavy canvas or thick webbing: 330°F (165°C), 50–60 psi, 12–16 seconds. Leather and suede: 285°F (140°C), very light pressure (10–20 psi) for 8–10 seconds–prefer sewing after light adhesive tack. Foam-backed or puff patches: 280°F (140°C), minimal pressure, 6–8 seconds; avoid direct heavy pressing. Household iron equivalents: high cotton/linen setting ≈ 320°F, set steam off, press firmly 15–25 seconds with a cloth and do not slide the iron.

Always pre-press the fabric for 3–5 seconds to remove moisture and creases. Test settings on a scrap of the same material and check wash resistance before final application.

Sewing and reinforcement specifications

Machine sewing: use a 90/14 or 100/16 topstitch/denim needle with polyester or bonded nylon thread (heavy-duty, approx. 30–40 wt). Straight topstitch: 2.5–3.0 mm stitch length, stitch line 1.5–2.0 mm from patch edge. Zigzag edge: width 2.5–3.5 mm, length 1.5–2.0 mm for catch and abrasion resistance. Add 3–5 bar-tacks (3–4 mm wide, 3–5 passes) at high-stress corners or strap attachment points.

Hand sewing: use waxed polyester or bonded nylon thread and a sturdy upholstery or leather needle. Use a saddle stitch or backstitch with 2–3 mm spacing; make stitches close to the edge (1.5–2 mm) and finish with a hidden knot plus a small dab of clear fabric cement on the knot for extra security.

Stabilizers and finishing: place a cut-away stabilizer behind thin or stretchy fabrics; use tear-away for temporary support. Trim excess adhesive from the perimeter after cooling and run a narrow topstitch around the patch to prevent peeling over repeated washes. Allow 24 hours before first wash; machine wash cold (30°C), gentle cycle, inside-out, air-dry or tumble low. If lifting occurs, re-press with protective cloth for 8–10 seconds then reinforce with stitches as described.

Paint and stencil step-by-step: fabric prep, layering, and washproof sealing

Use water-based textile paint or artist acrylic mixed 1:1 with textile medium, apply with a foam pouncer in thin passes, build color with 2–4 thin layers, then heat-set after a full 24-hour cure for best durability.

Step 1 – Fabric prep: machine-wash with a grease-cutting detergent, skip fabric softener, air-dry or tumble-dry fully, then iron flat on the appropriate heat setting. Degrease painted area with 70% isopropyl alcohol and let evaporate 5–10 minutes. Stretch the fabric over a rigid board and secure edges with painter’s tape to eliminate movement during stenciling.

Step 2 – Stencil adhesion and bleed control: apply low-tack repositionable spray adhesive to the stencil’s back from 8–12″ (20–30 cm), press firmly, and test a small corner. For surgical crisp edges, do a thin “seal” coat using clear textile medium thinned 10–20% with water around stencil edges; let that tack 5–10 minutes before color application.

Step 3 – Application technique: load a small amount of paint on the pouncer, offload on paper to remove excess; use vertical tapping motion, not brushing. Maintain a dry-ish tool: each pass should deposit ~10–15% opacity; overlap passes by ~50% to avoid striping. For spray paint, keep 8–12″ distance and use 2–3 light passes rather than one heavy coat.

Step 4 – Layer timing and opacity targets: allow 10–20 minutes between thin coats in moderate humidity (20–60%); expect 2 coats for pastels, 3–4 for solid opaque colors or metallics. Use a magnifier or bright side-lighting to spot micro-bleeds; correct immediately with a clean damp Q-tip before paint cures.

Step 5 – Edge cleanup and small details: remove stencil when paint is tacky but not fully cured – typically 15–30 minutes after the last thin coat – pulling straight up to avoid smearing. For fine lines, touch up with a detail round brush (size 0–2) thinned 5–10% with textile medium.

Step 6 – Cure and heat-set: allow a minimum of 24 hours dry time at room temperature (21–25°C). Heat-set through a cotton pressing cloth with a household iron on medium (no steam) for 3–4 minutes while moving slowly, or use a clothes dryer on high for 30 minutes. Always test on a scrap sample first to confirm fabric and pigment tolerance.

Step 7 – Washproof sealing options: choose either (A) a flexible water-based fabric sealer applied in two light spray passes (15–20 cm distance) with 30 minutes between coats, or (B) a diluted textile varnish brushed thinly and cross-brushed for full coverage. After sealer cures 24 hours, perform a cold-water wash test; if excessive dye migration or cracking appears, remove sealer and retry with a different product on a test swatch.

Maintenance and performance: wait 72 hours after final heat-set/sealer cure before routine laundering; wash inside-out on a gentle cycle, line-dry or tumble low. For heavy-use packs or gear made by premium manufacturers consult model specs for material compatibility – see best luggage brands for men. For long sessions of detailed work, consider hydration and simple supplements such as reading which is better amino acids or whey protein to plan breaks and recovery.

Add pockets and organizers by measuring, cutting fabric and using quick hand-sewing techniques

Measure the object to be stored; add 12 mm (1/2″) total ease in width and 25 mm (1″) for the top hem plus 10 mm (3/8″) for the bottom seam when planning pocket pieces.

Templates and measurements

- Standard allowances: seam allowance 10 mm (3/8″) per edge for medium fabrics, increase to 15 mm (5/8″) for thick materials. Top hem 12–25 mm (1/2″–1″).

- Example: smartphone 150×70 mm → cut pocket 175×100 mm (height = 150 + 25 top hem + 10 bottom seam; width = 70 + 2×10 seam + 8 ease → round to practical cut).

- Pen slots: width = pen diameter + 6–8 mm ease; cut strip height = pen length + 12 mm for tuck-over hem.

- Card slots: stack pieces 70×90 mm for standard cards; leave 6 mm overlap between slots and stitch at 6–8 mm intervals to form channels.

- Zipper pocket: back piece = pocket width + 2×10 mm seam; front facing = same width + 12–15 mm for zipper tape overlap.

Cutting, stabilizing and layout

- Place pattern on straight grain; mark with chalk or fabric pen. Use rotary cutter and steel ruler for straight edges. Cut interfacing 2–3 mm smaller than fabric edges to avoid raw fusible at seams.

- Fusible interfacing: medium-weight (SF101-type) for cotton/heavy canvas alternatives; lightweight woven or nylon-specific fusible for ripstop/nylon. Apply per manufacturer’s temperature/time–press with steam where fabric allows.

- Lay pieces so seams fall away from main load lines and zippers; position internal dividers 15–25 mm from side seams to prevent seam stress.

Fast, reliable hand techniques yield durable results with minimal gear.

- Thread & needle: use bonded nylon or heavy polyester thread; double the thread and wax it if available. For medium fabrics choose a strong hand needle (sharps #5–7); for thick layers use a heavy upholstery/awling needle.

- Backstitch for primary seams: 3–4 mm stitch length, reinforcing start/end with three small reverse stitches or an extra backstitch. Backstitch equals near machine-strength hold.

- Whipstitch/overcast for raw edges: 3 mm spacing to keep synthetic edges tidy or when adding a lining. Use small, tight stitches for narrow hems.

- Bar tack reinforcement: make 20–30 small straight stitches over a 6–10 mm area at pocket corners and strap anchors; maintain tension so stitches bunch slightly for a compact lock.

- Topstitching: place 3–5 mm from the finished edge with 3.5–4 mm stitch length to flatten seams and secure facings. Use a thimble for consistent pressure on heavy layers.

- Assemble slip pocket:

- Fuse interfacing to pocket outer, fold top hem 12–25 mm twice and baste. Edge-stitch hem 2–3 mm from fold.

- Place pocket on lining or interior panel, pin or clip at 6–8 mm from edge, baste with running stitch.

- Backstitch sides from bottom to top; finish with bar tack at each top corner.

- Make a small zip pocket:

- Attach zipper to facing using a 12–15 mm overlap; baste zipper in place with long running stitches, then secure with backstitch along tape edge.

- Sew pocket bag pieces together with 10 mm seams, clip corners, turn, and close opening with ladder/slip stitch for invisible finish.

- Create pen/card organizer:

- Sew vertical stitch lines at measured intervals; use a double backstitch at each end and a short bar tack at high-stress ends.

- Fold organizer to create a notch or tuck for thicker items; edge-stitch to fix position.

Final checks: trim seam allowances to reduce bulk at corners, press seams flat with a tailor’s clapper or fingertip pressure, and test pockets with intended items; add additional bar-tacks if any seam shows stretch.

Upgrade straps and hardware: fit buckles, add padding and mount carabiners without weakening fabric

Swap low-quality plastic clips for acetal or stainless steel side-release buckles rated ≥1,000 lbf; match buckle slot to webbing width (20 mm, 25 mm) and test fit before cutting existing straps. For sewn replacements, feed webbing 25–30 mm through the buckle, fold with a 10–15 mm overlap and secure with a box-x stitch (stitch length 3–4 mm) using bonded nylon thread (size #69 or 0.5–0.8 mm). Add a 40×40 mm Cordura or nylon backing patch under the stitch area to distribute load and prevent seam tear-out.

For extra shoulder comfort, glue a 6–10 mm closed-cell EVA foam strip to the underside of the strap, thicker for heavy loads (10–12 mm). Use contact cement or 3M Hi-Strength 90 spray adhesive; press for 60 seconds and clamp 2–3 minutes. Encase foam in a cover cut 6–8 mm larger than foam per edge and topstitch with a 3.5–4.0 mm straight stitch, then reinforce ends with 10 mm bar-tacks spaced 15–20 mm apart.

Add gear attachment points without punching holes by sewing webbing loops onto existing seams or into strap channels. Cut a 50–70 mm length of 20–25 mm webbing, fold into a loop sized for the carabiner, place a 30×60 mm backing patch under the base and sew three parallel lines: first straight stitch at 3.5 mm, then box-x over the loop with 6–8 mm stitch length. Avoid grommets that perforate main fabric unless a backing plate is used on the reverse side.

Use lightweight accessory carabiners (aluminum, 1–3 kN rating) for keys and small items; do not rely on these fittings for load-bearing tasks involving humans. Position carabiner loops away from zipper tape and main seam allowances–place them 20–30 mm from those elements to prevent stress concentration. If adding multiple loops, space them 40–60 mm apart and stagger vertically to reduce fabric puckering.

| Component | Material | Webbing width | Minimum load rating | Best application |

|---|---|---|---|---|

| Side-release buckle | Acetal | 20 mm / 25 mm | 1,000 lbf (≈4.4 kN) | Main strap closure, adjustable sternum straps |

| Quick-release metal buckle | Stainless steel | 25 mm | 1,200–2,000 lbf (≈5.3–8.9 kN) | Heavy-duty load points, waist belts |

| Ladder-lock | Acetal / Aluminum | 20 mm / 25 mm | 800–1,200 lbf (≈3.6–5.3 kN) | Length adjusters, non-primary load |

| Accessory carabiner | Aluminum | Use with 20–25 mm loop | 1–3 kN | Keys, water bottles, light tools |

When retrofitting, always test sewn joints with a 3–5× expected working load before regular use; inspect stitches and backing patches after 24 hours of use and re-stitch if any thread abrasion appears. For rivets or grommets, add a backing plate or internal patch sized at least twice the hole diameter to prevent local fabric failure.