Immediate action: swap a worn slider for a size-matched metal replacement (common sizes: No.3 for lightweight coil tape, No.5 for medium applications, No.8 for heavy molded teeth) and crimp replacement stops with flat-nose pliers to re-establish travel limits. For coil-type closures choose a slider with inner wings to avoid fabric snag; for molded teeth pick a wider throat slider that matches tooth profile.

Tools: flat-nose and needle-nose pliers, seam ripper, replacement sliders and stops, heavy polyester or bonded nylon thread, upholstery needle or awl, candle wax or dry graphite, small screwdriver or pin. Keep a spare No.5 metal slider and a pair of metal stops in your kit: they cover most mid-size repairs in the field.

If the pull is stuck on fabric, gently work the fabric free while applying a thin film of candle wax or a graphite pencil along the teeth; do not use liquid oils. For a slider that no longer brings teeth together, use needle-nose pliers to squeeze the slider sides by approximately 0.5–1.0 mm total closure (test on the spine of the slider) until engagement returns. When teeth are misaligned, run the slider slowly from the broken end toward the top while keeping the tape straight and tensioned; stop if resistance spikes and inspect for bent teeth.

For missing end stops: add a crimp-on metal stop 3–5 mm from the tape edge or replace with a tightly sewn bar-tack made of 8–12 passes of heavy thread, width about 4–6 mm. Replace a torn tape when you observe >5 consecutive missing or deformed teeth, or when the tape fabric frays beyond 10–12 mm inside the slider travel zone; removing and re-sewing a new tape requires seam allowance of 6–8 mm and backstitching at 3–4 mm intervals for strength.

Maintenance tips: blow or brush grit out of the channel before lubrication, apply dry lubricant sparingly to the teeth or coil, and check sliders and stops every 3–6 months under normal use. If metal teeth are corroded, swap to a corrosion-resistant replacement or replace the whole closure–partial repairs on extensively corroded components reduce service life.

Free a slider jammed by fabric, dirt, or corrosion

Apply one small drop of silicone spray or rub a graphite pencil tip into the slider, then hold the surrounding fabric away with one hand and gently move the slider back and forth 3–6 mm while extracting trapped material with fine tweezers or a sewing needle.

Trapped fabric

Use a pointed tool (seam ripper, safety pin) to tease the thread or cloth from between the teeth; grip the protruding fiber with tweezers and pull it straight out while easing the slider the same direction. If the material is tightly wedged, press the slider slightly open with flat-nose pliers (1–2 mm) to release pressure, then repeat the extraction. After clearance, run a pencil lead or apply a pea-size smear of paraffin wax along the teeth to restore smooth travel.

Dirt, sticky residue, and corrosion

For grime: brush the track with a soft toothbrush and warm soapy water, rinse, blot dry, then lubricate with silicone spray or candle wax. For sticky or oily deposits: dab 70% isopropyl alcohol onto a cotton swab and clean the slider and teeth; allow 5 minutes to evaporate before lubricating. For light corrosion on metal sliders: apply a penetrating oil (one small spray), wait 10 minutes, then work the slider gently; for heavy rust, soak the metal part in white vinegar for 20–30 minutes, scrub with an old toothbrush, rinse, dry thoroughly, and then protect with a thin coat of silicone or a light machine oil. Avoid soaking fabric panels; mask them with plastic while treating metal components.

Realign separated teeth without replacing the entire zipper

Use needle-nose pliers, fine tweezers, a 400–600 grit jeweler’s file and a bright lamp; work with the tape flat on a hard surface and keep the area immobilized with a clip or clamp.

Assess material and damage: metal teeth, molded plastic teeth, and nylon coil behave differently. Measure the gap in millimetres; if more than ~20 mm of consecutive teeth are missing or three-plus adjacent crowns are cracked, full replacement of the chain is recommended.

Metal teeth: with tweezers align opposing crowns so they meet evenly. Grip the base of each misaligned tooth with pliers and compress toward the tape by roughly 0.5–1.0 mm to re-seat the tooth into mesh. Remove sharp burrs with light file strokes (2–6 passes), checking engagement after every 3–4 teeth.

Molded plastic teeth: warm the area with a hairdryer at 60–80°C for 6–10 seconds to soften the polymer, hold the tape taut, then press crowns back into position using a flat screwdriver or a smooth metal block. Cool under a metal ruler for 30–60 seconds to set shape. Do not use open flame or exceed 90°C.

Nylon coil: lay both tapes flat and use a blunt sewing needle to nudge errant loops into the coil channel. Lock the corrected stretch by stitching a row of heavy polyester thread 3–5 mm from the coil for 30–50 mm; knot securely and trim tails close to the knot.

Stabilize the repair without replacing the full chain: fit a new metal stop 5–10 mm below the repaired area and crimp with flat-nose pliers to prevent slippage. If the slider fails to re-engage the realigned run, reduce its internal width by compressing the back plate by about 0.3–0.6 mm in 0.1–0.2 mm increments, testing engagement after each squeeze.

Test the repair by running the pull slowly across the section 8–10 times under light tension. If skipping continues after two adjustment cycles (compression, filing, reheating/resculpting), the chain integrity is compromised and full replacement of the track is the most reliable solution.

Tighten or swap a worn slider that won’t close the teeth

Tightly compress the slider’s side walls with two pliers to restore the internal channel; if teeth still separate or the channel is cracked, replace the slider with one matching the tape width and tooth type.

Diagnosis

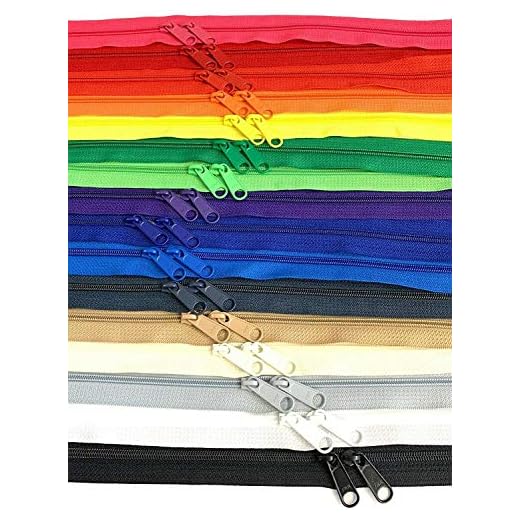

Inspect the slider for these specific signs: visible gap between side walls, crushed or widened channel where teeth enter, internal grooves worn smooth, or a cracked/broken body. Identify the tooth type before ordering parts: coil (nylon spiral), molded plastic, or metal teeth. Measure the tape width at the point the slider rides (use calipers or a ruler): ~3 mm → size #3, ~5 mm → size #5, ~8 mm → size #8. Verify whether the original was closed-end, open-end, or two-way.

Tightening technique

Tools: two pairs of pliers (needle-nose and flat-nose), leather or cloth tape to protect the slider, small Phillips screwdriver (for prying stops if present), and a test strip of the same tape if available.

Steps:

1) Place the slider over engaged teeth so it sits in its natural position. 2) Wrap jaws with tape to avoid gouging. 3) Using the flat-nose pliers, apply gentle inward pressure to the rear side walls; pinch in 1–2 light squeezes and test by drawing the slider down–repeat in small increments until the slider mates the teeth consistently. 4) If still loose, apply one or two slight squeezes to the front (nose) of the slider, being careful not to collapse the channel. 5) Clean and apply a tiny amount of dry lubricant (graphite or paraffin) to improve bite. Test through full travel at least five cycles.

Signs you’ve gone too far: slider grabs and jams, tape fibers get crushed, or teeth deform–reverse by gently bending side walls back or replace the slider.

| Slider size | Approx. tooth width | Typical use | Replacement note |

|---|---|---|---|

| #3 | ~3 mm | light garments, small pouches | use nylon coil slider matching tape width |

| #5 | ~5 mm | mid-weight apparel, day bags | available in metal or molded; match tooth style |

| #8 | ~8 mm | heavy gear, luggage | choose heavy-duty metal slider; verify closed/open end |

Replacement steps: remove the top stop (cut or pry off), slide off the old slider, slide the new slider on in the correct orientation so the pull tab faces outward and teeth seat in the channel, reattach or crimp a metal top stop, or fold the tape end and sew several reinforced stitches across the tape with heavy nylon thread. After replacement, run the slider through multiple cycles and trim or seal any excess tape end.

Replace a missing or broken pull with household alternatives

Use a split key ring or a short loop of cord as the fastest working replacement; for longer-lasting repair choose paracord plus a bead or a small crimp sleeve.

Quick temporary options

- Paperclip loop – straighten then bend into a teardrop (use 0.8–1.0 mm wire). Thread through the slider eye, twist ends together and tuck them inside the loop. Holds for light use; rust-prone on wet items.

- Safety pin – thread the pin through the slider tab hole and close. Ideal for single-trip emergency use; avoid on delicate fabrics that can snag.

- Key ring/split ring – 10–12 mm diameter (¼–½ in). Open with fingernail or pliers, slip through slider hole, attach as a durable metal pull suitable for heavy loads.

- Straightened paper clip + tape – create a small loop and wrap 5–10 mm of electrical tape around the bite for grip and to conceal sharp ends.

Durable DIY pulls and installation details

- Paracord loop: cut 4–6 cm of 2–3 mm cord; fold in half and pass folded end through slider eye; feed loose ends through the folded loop and pull tight (larks head). Add a 6–8 mm bead and melt ends (~1–2 s with lighter) then press to flatten. Lasts months under normal use.

- Shoelace or nylon cord + crimp sleeve: thread cord through slider, position a 2–3 mm aluminum crimp sleeve, compress twice with pliers. Trim excess and melt tip to prevent fray. Use for medium-duty applications.

- Heat-shrink tubing over split ring or wire loop: slide 8–12 mm of 2:1 tubing onto loop, shrink with lighter 1–2 s from 10–12 cm distance; provides better grip and protects slider finish.

- Fishing swivel or small snap hook: pass swivel eye through slider and use swivel as pull for quick detach and minimal wear; choose size No. 7–12 depending on slider hole diameter.

Tips for selecting method: metal rings or swivels for heavy or frequent use; paracord or crimped cords for balanced durability and comfort; paperclips or pins only for temporary service. After installing, perform 10–15 full open/close cycles and tug the pull with ~5–10 kg of force to confirm security. Replace with a purpose-made replacement pull when long-term reliability is required.

Prevent slider from sliding open: adjust stops and slider tension

Set or crimp top stops 2–3 mm beyond the last tooth and tighten the slider plates in 0.25–0.5 mm increments until the slider resists a 2 kg pull (≈20 N); if no metal stop exists, add a 3–4 mm length of heat-shrink tubing or a stitched bar-tack placed 2–3 mm from the last tooth.

Tools & measurements

Needle-nose pliers, flat-nose pliers wrapped in electrical tape, small ruler (mm), heat-shrink tubing 3 mm ID (cut to 3–4 mm length), heavy-duty thread and upholstery needle, jeweler’s crimp sleeves (3–4 mm) or brass ferrules, lighter or heat gun, small flat file, digital kitchen scale (kg) for testing.

Step-by-step adjustments and tests

1) Inspect: slide the pull to the end and check for existing stops. Measure distance from last tooth to stop – target 2–3 mm. If a metal stop is loose, position it square to the tape and compress with flat-nose pliers until thickness is ~30% less or the slider resists a 2 kg hand-hold.

2) Add a stop if absent: slip a 3–4 mm heat-shrink over the tape with the slider at the end; heat until tubing grips the tape and occupies ~2 mm of vertical clearance. Alternatively, place a crimp sleeve across the tape and crimp with pliers; finish with one dab of clear fabric glue to prevent migration.

3) Increase slider bite: protect the slider with thin tape, then gently close the front and back plates using flat-nose pliers in small steps (0.25–0.5 mm). Test after each tweak by pulling the slider against the stop while hanging a 1–2 kg weight; stop when the slider no longer drifts under load but still moves by hand.

4) Reinforce with stitching: for textile closures, sew a 6–10 pass bar-tack 2–3 mm from the last tooth across full tape width; use heavy nylon or polyester thread and knot on the inside to avoid snagging. This prevents slider passage without altering slider geometry.

5) Validation: run the slider through 20 open/close cycles, then attach 2–5 kg for 30 seconds. If slip occurs, either move the stop 1 mm closer to the teeth or add a second stop 1.5–2 mm apart. Avoid over-crimping; excessive compression can deform teeth or split coil tape.

Quick reference link: are drones legal in kenya

Reattach a slider that has come off one side of the track

Insert the intact tape edge into the slider’s narrower face at a shallow angle (about 20°–30°), push until the first few teeth seat inside the channel, then feed the opposite tape straight into the other face while pulling the slider away from the head – the teeth should mesh immediately.

Tools: needle-nose pliers, small flat screwdriver, tweezers, diagonal cutters, graphite pencil or paraffin wax for lubrication.

Step 1: Clear 2–3 teeth near the slider entry with tweezers; remove lint or threads so the channel is unobstructed.

Step 2: With the slider lying flat, slide the exposed tape edge into the lower groove first (the groove that lines up with the slider’s floor). Align the central tooth row under the slider tongue and push the tape forward until resistance disappears.

Step 3: Feed the second tape directly into the opposite groove while gently pulling the slider in the same direction. Maintain steady, even tension on both tapes to prevent teeth misalignment.

Tighten the grip: If the slider slips without closing teeth, apply a single, gentle squeeze across the back of the slider with needle-nose pliers – compress 0.3–1.0 mm total. Test after each small squeeze; stop when the slider engages reliably. Avoid over-compression that distorts the tongue or blocks motion.

When a metal top stop blocks re-entry: Pry the stop outward with a flat screwdriver or cut it off with diagonal cutters, reattach the slider, then replace the stop with a crimp-on metal stop or a few reinforced machine stitches to prevent future separation.

Final checks: Run the slider 5–10 full cycles to confirm smooth meshing; if it catches, rub 3–5 gentle strokes of a graphite pencil or a small amount of paraffin along the teeth and wipe excess. For compatibility notes on related gear see best umbrella stroller with reclining seat.