Direct advice: Avoid placing pressurized insect-repellent containers in the aircraft hold: changes in cabin pressure and temperature increase the risk of rupture, leakage and ignition, and many airlines treat such items as dangerous goods. Prior to travel, verify the carrier’s hazardous‑materials rules and consult the applicable national aviation authority or IATA Dangerous Goods Regulations for the route.

Safer alternatives: For cabin baggage, use pump bottles or solid/impregnated products packed in accordance with the liquids rule (individual containers limited to 3.4 oz / 100 ml inside a single resealable clear bag). Consider wipes, treated clothing, or purchasing insect repellent at the destination to avoid transporting pressurized containers altogether.

If transportation of pressurized containers is unavoidable: obtain explicit airline permission; retain original labeling and instructions; secure caps with tape; place each container upright inside an absorbent layer and a sealed plastic bag; separate from batteries and other hazardous items; declare items at check‑in if requested by the carrier. When in doubt, ship via a certified courier under the appropriate dangerous‑goods manifest or leave the containers behind and procure replacements locally.

TSA and airline rules for transporting pressurized insect repellent in the aircraft hold

Recommendation: Transport only non‑flammable pressurized insect‑repellent containers that comply with DOT limited‑quantity limits – single containers must not exceed 500 mL (≈17 fl oz) and the aggregate per passenger must stay within 2 kg (≈70 oz); products listing flammable propellants (butane, propane, isobutane) or showing a flame pictogram are not permitted in either cabin or aircraft hold.

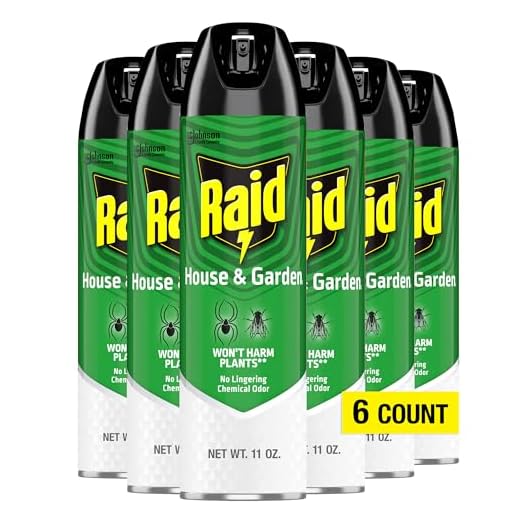

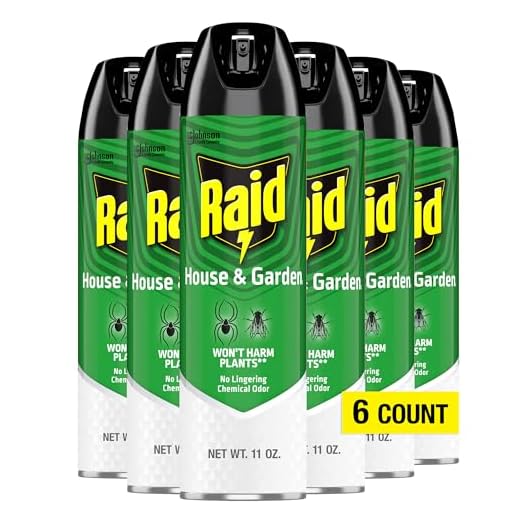

Label and documentation checks: verify the product label for hazard statements and look up the Safety Data Sheet (SDS) before travel; if the SDS indicates flammable propellant or aerosol hazard class, do not attempt air transport. TSA permits non‑flammable consumer repellents under limited‑quantity rules but final acceptance rests with the carrier and screeners.

Airline and international differences: carriers set their own restrictions beyond TSA guidance–some prohibit all pressurized repellents, others require valve locks and original caps. For international flights, import and airline rules may be stricter; consult the airline and destination customs or regulatory website at least 48 hours before departure.

Packing checklist

Seal original cap, place container in a zippered plastic bag, cushion on all sides with clothing, avoid packing near sharp items, limit quantity to regulatory maximums, retain purchase receipt and SDS (printed or electronic) for check‑in if requested.

If refused at check‑in or screening

Options: leave the item behind, ship via a ground carrier that accepts hazardous household products (follow IATA/ICAO and DOT requirements for shipment), or purchase non‑pressurized formulations (lotions, wipes, pump sprays labeled non‑pressurized) at the destination. For disputes, request a supervisor at the screening checkpoint or contact the airline’s customer service for written clarification of policy.

How to read product labels: flammable, pressurized, and allowed quantity limits

Check three items first: UN number, hazard codes/pictograms, and net quantity. Presence of UN1950 or hazard codes such as H220, H225, H229 or H280 signals a pressurized, flammable product that will be treated under transport regulations.

Key label elements and what they mean

UN number: a four-digit code (example: UN1950) that identifies class and handling rules for transport. If present, assume regulatory controls apply.

Signal word and pictograms: “Danger” or “Warning” plus a flame pictogram = flammable; gas cylinder icon = gas under pressure. These visuals override casual wording like “non-flammable” printed elsewhere.

Hazard statements (H‑codes): H220 – extremely flammable gas; H225 – highly flammable liquid and vapor; H229 – pressurized container, may burst if heated; H280 – contains gas under pressure. Presence of any H‑code indicates a specific hazard category to report to carriers or safety data sheets.

Precautionary text: lines such as “Do not puncture or incinerate,” “Protect from sunlight,” or “Do not expose to temperatures above 50°C / 122°F” confirm pressurised contents and handling limits that affect transportability and storage.

Net quantity, unit conversions and quick thresholds

Find the net amount: displayed as weight (g, oz) or volume (mL, fl oz). Common label examples: “Net wt. 6 oz (170 g)” or “Net volume 150 mL.” Convert if needed: 1 oz = 28.35 g; 1 fl oz ≈ 29.57 mL.

Practical threshold: containers larger than ~500 mL or >500 g are frequently subject to stricter carriage limits under air transport rules; containers under that size are more often covered by “limited quantity” or “consumer commodity” exceptions, but carrier-specific rules still apply.

Look for exemption wording: phrases such as “Limited quantity,” “Consumer commodity,” or “Not restricted for carriage” (and accompanying regulatory codes) indicate potential exceptions; absence of such wording means full dangerous-goods treatment may apply.

Actionable steps: read and photograph the label, note UN number and H‑codes, record net quantity (convert to grams or mL), and consult the carrier’s dangerous-goods guidance or the product SDS before attempting transport.

Packing best practices to prevent leaks, bursts, and pressure changes in stowed baggage

Store pressurized insect repellent inside a sealed heavy-duty plastic bag (minimum 3 mil gauge), tape the actuator, snap on the factory cap, then place the item upright in the geometric center of a hard-shell suitcase surrounded by at least 2 inches (5 cm) of soft clothing above, below and on all sides.

Tape protocol: wrap high-adhesion cloth or PVC tape around the actuator stem twice, then apply a small square of tape over the cap-to-body seam to stop accidental depressurization from impact. Use tamper-evident tape for visual inspection by ground staff.

Secondary containment: use two nested sealable bags – inner bag for immediate containment, outer bag for redundancy – plus one layer of absorbent material (microfiber towel or travel absorbent pad) inside the inner bag to capture any tiny leaks without contaminating garments.

Orientation and placement: secure canisters upright in the suitcase core; wedge with rolled clothing items to prevent tipping. Avoid placement adjacent to wheels, external zippers, or suitcase walls thinner than 5 mm to reduce risk of crush damage from conveyor machinery.

Hard-shell versus soft-sided: select rigid-shell cases with reinforced corners and internal compression straps for better protection during transfers – see best luggage for yacht week for examples of durable designs suited to frequent handling. For small soft bags or backpacks used as checked-equivalents, follow the same double-bagging and padding steps; lightweight options are reviewed at best jansport backpack for high school.

Temperature and pressure notes: avoid exposing pressurized containers to temperatures above 50°C (122°F) before drop-off; on long ground waits, move bags into shaded, cool areas. Do not attempt to vent or modify canisters to relieve pressure.

| Action | Materials | Target measure | Why |

|---|---|---|---|

| Actuator secure | Cloth/PVC tape, factory cap | 2 tape wraps + taped seam | Prevents accidental discharge from impact or pressure changes |

| Double containment | Inner + outer heavy-duty zip bags (≥3 mil), absorbent pad | Two nested bags; 1 absorbent pad | Reduces risk of clothes contamination and provides redundancy |

| Padding | Rolled clothing, microfiber towel | ≥2 inches (5 cm) around item | Cushions against crushing and vibration |

| Placement | Hard-shell suitcase core, compression straps | Center of case; upright orientation | Minimizes mechanical stress during handling |

| Visual inspection | Tamper-evident tape, clear outer bag | Visible seal before and after transit | Facilitates detection of leaks or policy checks |

For multiple canisters, separate each item with its own double-bag and maintain at least 2 inches (5 cm) of separation between units inside the case; pack heavier items below and around them to avoid point loads that can rupture valves.

When and How to Declare or Notify the Airline about Pressurized Insect Repellent

Declare pressurized insect‑repellent cans at the ticket counter or to the carrier’s dangerous‑goods office whenever a single container exceeds 0.5 kg (500 g) or the combined net mass per passenger exceeds 2 kg (IATA PI 203); larger quantities must be shipped as dangerous goods cargo with airline approval.

When to declare

Declare when product labelling shows flammable wording, GHS flammability pictograms, or contains hydrocarbon propellants (butane, propane, isobutane) even if each can is under 500 g.

Declare when transit involves carriers or countries that explicitly restrict insecticide/insect‑repellent aerosols–airline policy may be stricter than IATA/TSA and may ban certain formulations.

Declare when multiple cans combined exceed the PI 203 passenger total (2 kg) or when transporting more than a few personal‑use units; commercial quantities require a Shipper’s Declaration for Dangerous Goods.

How to notify the airline

Contact the carrier’s dangerous‑goods (DG) unit before travel via the airline website or published DG phone/email. Provide product name, net mass per container (g/ml), number of units, UN number (commonly UN1950), SDS, and statement of intended stowage (hold or cabin).

Request written confirmation or an approved DG acceptance code; present that confirmation plus the SDS at the ticket counter/baggage drop. Ground staff must record acceptance for the flight manifest.

For connections on different carriers, notify each operator and present approvals at each transfer point. If airline approval is refused, arrange commercial cargo shipment under IATA Dangerous Goods Regulations.

Failure to declare hazardous cans can result in confiscation, fines, denied boarding, or safety delays; retain all airline communications until after the trip.

Steps to take if TSA or the airline confiscates or disposes of pressurized insect repellent from hold baggage

Request written documentation from the checkpoint agent immediately.

- Obtain the screening tag or confiscation receipt; photograph that tag and any markings placed on the bag.

- Record names, badge or employee numbers, and the screening lane/terminal. Note exact date and time of the incident.

- Photograph the bag interior, product packaging (label, UPC, net weight in oz or g, hazard symbols), boarding pass and bag claim tag before leaving the area.

- Preserve proof of purchase: original receipt, order confirmation, credit-card transaction line item or invoice. If purchase proof unavailable, note estimated retail value and where item was bought.

- If an agent states the item was destroyed, request a written statement of destruction or disposal procedure and a reference or incident number for follow-up.

- Ask whether an internal property report was completed and request the report number or the supervisor’s contact details.

File formal reports and claims.

- Submit a complaint to the Transportation Security Administration via https://www.tsa.gov/contact. Include incident number, screening tag photo, boarding pass image, bag claim tag, proof of purchase, product photos and agent names.

- File a baggage/contents claim with the operating carrier if the item was within hold baggage handled by the airline. Use the airline’s baggage-claims portal and attach the same documentation as above.

- If the item had significant monetary or sentimental value, open a claim with travel insurance or the payment-card issuer used for purchase; attach the airline/TSA reports.

Escalation and follow-up protocol.

- Keep copies of every submission and request a written confirmation or case number for each report.

- Follow up regularly: reference case numbers, supply any additional documentation requested, and request expected resolution timelines in writing.

- If responses are insufficient after documented attempts, request escalation to a supervisor or the airline’s customer-relations manager; keep all correspondence timestamps.

- If theft or mishandling is suspected, obtain a local police report from airport law enforcement and attach it to all claims.

What to include in every communication (concise checklist):

- Incident date, airport name, terminal and screening lane

- Passenger name as printed on boarding pass, flight number, seat, bag claim tag number

- Detailed item description: brand, net weight (oz/g), UPC or serial, condition at packing, estimated value

- Photos of product, packaging labels, bag interior, confiscation tag and boarding documents

- Proof of purchase and receipts

- Names/badge numbers of agents and any supervisor contact info

Recovery expectations and compensation notes.

- TSA typically enforces hazardous-material rules; regulatory confiscation often precludes reimbursement by TSA. Airline liability for stowed-bag contents varies by carrier and fare class; airline claims processes or travel insurance may provide reimbursement for documented loss.

- Maintain all original documentation for any claim; lack of purchase proof reduces likelihood of full reimbursement.

Preventive recommendation for future travel: ship pressurized insect-control cans via ground courier or purchase permitted replacements at destination to avoid screening losses.

Related resource for pet travel gear: best active winter sweaters for small breed dogs.

FAQ:

Can I put aerosol bug spray in my checked luggage on a flight?

Many airlines and aviation regulators permit consumer aerosol insect repellents in checked baggage, but there are limits. Check the product label: if it warns that the contents are flammable or under pressure in a way that restricts air transport, do not pack it. Keep the spray in its original container with the protective cap on, place it inside a sealed plastic bag to catch leaks, and cushion it with clothing to reduce the chance of puncture. Before you fly, review your airline’s rules and the security guidance for the country you depart from and arrive to, because some carriers or jurisdictions restrict certain aerosols or larger cans. At the airport security checkpoint staff may remove any item that appears unsafe.