Short answer: most pieces from that athletic apparel company offer water resistance rather than full impermeability; select items explicitly described with sealed seams, laminated or coated shells and a hydrostatic-head rating ≥5,000 mm for serious wet-weather protection.

Prioritize construction details: DWR (durable water-repellent) finish on the face fabric; a PU or TPU laminate for the shell; welded or taped seams instead of sewn-only joins; water-shedding zippers (e.g., coated YKK-style channels); roll-top or zip-flap closures; and an internal waterproof-lined laptop compartment. Capacity recommendations: 18–26 L for daily commuters, 26–35 L for multi-day carry with room for a rain cover.

Performance expectations: light showers and brief exposure typically stop at the DWR layer for several hours; sustained downpour will penetrate stitched seams and untreated zipper channels after roughly 30–90 minutes depending on fabric denier and coating. Full submersion remains unsafe unless the spec sheet lists specific hydrostatic-head numbers above 10,000 mm and seam-welded construction.

Simple tests and maintenance: spray a garden hose or spray bottle at 45° across the outer shell for 30–60 seconds and inspect interior dryness; check seams by running a damp finger inside the pack. Restore repellency with wash-in or spray-on products (Nikwax, Grangers or silicone-based sprays), avoid fabric softener, and re-seal small seam leaks with seam-sealer goo. Use a detachable rain cover for guaranteed protection in heavy weather.

Buying checklist: look for explicit millimeter ratings or the words “seam-sealed”/“fully taped”; request manufacturer specs for shell lamination and zipper type if missing; test returns and warranty terms for moisture-related claims. If no numeric rating appears, treat the item as splash- and shower-resistant rather than impervious to prolonged rain.

Which models are marketed as water-resistant versus fully impervious?

For everyday splash protection choose packs explicitly labeled “water‑repellent” or “DWR‑treated” on the product page; common examples from the brand’s city line include the City Adventurer family (15L, 23L, 25L) and several commuter/daypack styles that list a durable water‑repellent finish and coated fabric in the specs.

Items promoted as fully impervious to rain or immersion are rare in the catalog. Those that carry that claim will specify seam‑sealing or taped seams, welded or waterproof zippers, and a coated PU/TPU shell fabric. On official listings such models are grouped under technical or travel collections and are described with phrases such as “seam‑sealed,” “submersion tested,” or “marine‑grade coating.”

When deciding between splash protection and full protection, compare these explicit product details: fabric construction (plain nylon vs PU/TPU coated), presence of DWR, seam treatment (stitched vs taped), zipper type (standard vs welded/waterproof), and any manufacturer test claims or IPX rating. If you need reliable rainproof performance, prioritize packs that list taped seams + welded zippers rather than relying on DWR alone.

If a specific model name is absent from the listing, treat it as only splash‑resistant until the product page confirms taped seams or immersion testing; contact customer support for clarification before assuming full exposure protection.

How to perform a quick at-home water-resistance test on your pack

Perform a 5-minute drip-and-blot test to verify fabric coating integrity and seam leakage.

Materials: kitchen timer, measuring cup (100 ml), fine-mist spray bottle, paper towels, cotton swabs, flashlight, clean flat towel or table.

Prepare the pack: empty all compartments, fasten zippers and flaps, remove removable liners, place on the towel with interior access opened or turned inside-out when feasible.

Drip test: set the spray bottle to fine mist and apply 50–100 ml of room-temperature tap water distributed over three target zones–front panel, base, zipper line–spraying each zone for 60 seconds so water beads instead of streaming.

Blot and inspect: wait 60 seconds, then blot exterior gently; insert a paper towel or use a cotton swab along internal seams and behind any liners; use a flashlight to check for pinhole leaks or damp patches. Assessment criteria: pass = no detectable moisture inside; marginal = single tiny damp spot limited to a seam edge; fail = multiple damp spots, visible soak-through, or moisture at zipper tape.

Cup-pressure check for base: pour 200 ml into a shallow cup, press it flat against the base for 30 seconds while an assistant observes the interior; any liquid transfer indicates compromised coating or seam failure.

Zipper-line check: spray at a 30–45° angle toward the closed zipper for 30 seconds, then inspect the tape and pull-tab interface for seepage; leaks at zipper teeth normally require professional repair, zipper-tape replacement, or interior seam sealing.

If leakage appears, follow the care-label wash instructions, allow full drying for 24 hours, then apply a recommended durable water-repellent spray per product directions or treat interior seams with a clear seam sealer; retest after the sealer cures. For a canopy option to keep gear dry outdoors consider best selling home decor geneva canopy umbrella.

How fabric, seam sealing and zipper choices affect water protection

Choose packs that combine TPU-laminated face fabric, taped or welded seams and PU-coated or sealed zippers (or a roll-top closure) for reliable protection in heavy rain.

-

Fabric type and treatments

- Denier: 100–200D nylon or polyester offers light-weight durability; 400–600D increases abrasion resistance but does not automatically stop liquid ingress.

- Coatings: DWR (durable water repellant) makes water bead on the surface but won’t stop prolonged exposure. PU (polyurethane) coatings typically provide hydrostatic head roughly in the 1,500–5,000 mm range; TPU laminates commonly reach 5,000–20,000 mm – useful figures to compare manufacturer specs.

- Lamination vs coating: a visible, smooth inner film indicates lamination (higher barrier). Fabrics that are welded to that film eliminate needle holes that stitched constructions create.

-

Seam construction

- Stitched seams alone allow capillary wick-through at needle holes; expect seepage under sustained spray or submersion.

- Taped seams (heat-activated tape over stitch lines) prevent leakage along thread paths; quality tape is 5–10 mm wide and attached across the full stitch length.

- Welded or RF-bonded seams eliminate stitching entirely and provide the strongest barrier for serious exposure; commonly used on boat bags and dry sacks.

- Look inside pockets: visible tape or a continuous weld line indicates much higher liquid resistance than plain stitching.

-

Zipper types and layout

- Exposed coil zippers (standard) are the most common and the weakest point for liquid entry unless protected by an overlapping storm flap.

- PU- or rubber-coated water-repellent zippers (e.g., AquaGuard-style) shed spray; they are not fully impervious at high pressure or submersion but stop most rainfall.

- Sealed zippers with welded tape or molded waterproof profiles approach full closure integrity; typically seen on technical dry bags and photo gear cases.

- Closure design matters: top-loading with a storm flap or a roll-top closure yields better protection than exposed-length zippers on the front face of a pack.

-

Practical selection checklist

- For commuting and light rain: DWR-treated fabric + taped seams + storm-flap over zippers is sufficient.

- For outdoor activities or heavy downpours: choose TPU-laminated fabric + welded seams + sealed zippers or roll-top design.

- For gear that must stay dry (electronics, camera): prioritize welded seams and fully sealed zipper systems before considering fabric denier.

-

Maintenance and small repairs

- Reapply DWR after ~10–20 washes using a spray-on or wash-in product (brands: Nikwax, Grangers) following the manufacturer’s cleaning instructions.

- Repair seam-tape failures with adhesive seam tape or seam sealer (Gear Aid Seam Grip) for stitched seams; replace delaminated laminate only by a specialist.

- Keep coated zippers clean and lubricated with silicone-based zipper lubricant; avoid oil-based products that attract dirt and degrade coatings.

Inspect product specs for hydrostatic head or explicit terms like “laminated,” “taped seams,” “welded seams,” “sealed zipper” or “roll-top” to set realistic expectations for how much rain the bag will withstand.

Practical ways to protect laptops, phones and documents inside a pack during heavy rain

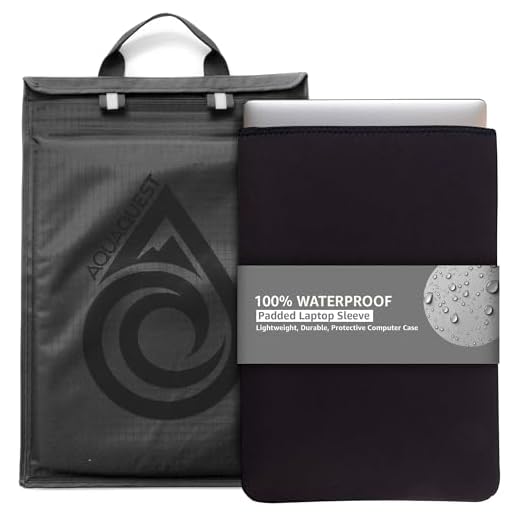

Primary defense: place the laptop in a snug neoprene sleeve (13″ or 15″ size to match device), then put that sleeve into a 8–12L roll-top dry sack rated IPX6 or higher; keep phone in an IP68-rated touch-through pouch with lanyard inside the same dry sack or a separate 1–3L pouch.

Document protection: double-bag papers in two heavy-gauge freezer bags (zip closure), insert between a rigid plastic folder or thin clipboard, then slide into an accordion folder or document sleeve before placing near the pack’s back panel to reduce bending.

Layering order inside the main compartment: outermost – small, frequently used items in a quick-access dry pouch; mid – documents in rigid sleeve; innermost against the body – laptop in neoprene + roll-top dry sack. This arrangement minimizes direct exposure when opening zips and reduces flex stress on electronics.

Zipper and opening management: orient main zipper openings downward where possible; tuck stubborn zippers under any storm flap. For additional sealing, run a short length of self-fusing silicone tape along the zipper line or use a thin roll-top pack cover stowed in its sleeve until needed.

Emergency improvised liners: use a thick contractor trash bag as an internal liner: place items inside, fold the top twice, and clip with a carabiner. For single-item protection, use a gallon zip-lock for documents or a quart bag for phones; press out air before sealing.

On-device precautions: power phones off or enable water-lock mode before storms, eject microSD/ SIM trays and keep them dry in a small zip bag, and remove any detachable battery or external drives when practical.

Immediate post-exposure routine: remove electronics, dry external moisture with lint-free cloth, open all ports and SIM trays, place devices horizontally with multiple silica gel packets (10–20 g each) in an enclosed container for 24–72 hours; avoid heat guns or high-temperature drying above 40°C.

Small kit to carry year-round: one 10L roll-top dry sack, one 2L phone pouch (IP68), 5–10 silica gel packets, three heavy-gauge freezer bags, a sheet of self-fusing silicone tape, and a compact pack cover – store the kit in an internal zipper pocket for instant deployment in heavy rain.

Use a technical wash, a DWR spray-on product, and dry-storage in a breathable bag to maintain the pack’s water protection.

Cleaning and reproofing protocol

Empty all pockets, remove detachable straps and foam inserts, then vacuum loose debris using a soft brush attachment. Spot-clean stains with a solution of 1 teaspoon (5 ml) mild detergent per 1 litre of lukewarm water; apply with a microfiber cloth or soft brush and rinse residue with a damp cloth. For a full clean use a specialist cleaner formulated for water-repellent textiles (for example, a “Tech Wash” style product) following the manufacturer’s dosage; hand-wash at ≤30°C and avoid machine cycles unless the care label explicitly permits them. Do not use bleach, fabric softener, or hot water – those degrade coatings and taped seams.

Once fabric is fully dry (typically 12–48 hours, depending on layer thickness), restore the durable water repellency (DWR) with a spray-on product designed for technical garments. Hold the aerosol or pump sprayer 15–20 cm from the surface and apply even, overlapping passes until slightly damp but not saturated; limit to two light coats on high-wear zones (base, flap, shoulder straps) with a 30–60 minute dwell between coats. For best durability, allow treated gear to cure 12–24 hours before use; some products improve bonding if gently warmed per label instructions (low-heat tumble or a warm room), but avoid direct heat or ironing unless the product specifies safe activation methods.

Storage, seams, zippers and small repairs

Store the pack empty, compartments unzipped, in a breathable cotton bag or pillowcase to prevent condensation. Ideal storage conditions: temperature 10–21°C (50–70°F) and relative humidity below 60%. Avoid sealed plastic containers and basements with fluctuating moisture; keep away from direct sunlight and chemical fumes (paint, solvents, new wood treatments). If preparing a move or long-term storage alongside luggage choices, compare options at best luggage for moving from us to europe.

Inspect taped seams and welds after heavy exposure. Small seam leaks can be sealed with a urethane-based seam sealer (e.g., Seam Grip or similar): clean and dry the area, apply a thin bead under the tape edge, smooth with a gloved finger or spatula, and allow 24–48 hours to cure. For failing zipper sliders, apply a silicone-based lubricant sparingly to the teeth and slider channel; replace sliders or add a protective flap if water protection is compromised. For nylon-coated fabrics showing wear, reproof high-abrasion areas more often (every 3–6 months with frequent rain use); for occasional exposure, annual reproofing usually suffices.

Avoid storing packs in garages or work areas where sawdust, treated lumber or chemical residues accumulate – if tools or projects exist nearby (for example, an outdoor project such as how to build a pallet fence for dogs), keep gear in a sealed cabinet or on a raised shelf to prevent contamination. Log reproofing dates on a label inside the main compartment so the next treatment is applied before the DWR fails and moisture starts migrating into linings and taped seams.