Set a domestic heat-press or flat heat tool to 150°C (302°F) for cotton and cotton-blend fabrics; reduce to 120°C (248°F) for polyester/nylon surfaces. Position the emblem, slide a piece of stiff cardboard inside the daypack to create a firm flat surface, cover the motif with a thin cotton cloth or parchment, press with steady, even pressure for 20–30 seconds, then allow the area to cool completely before flexing or loading the bag.

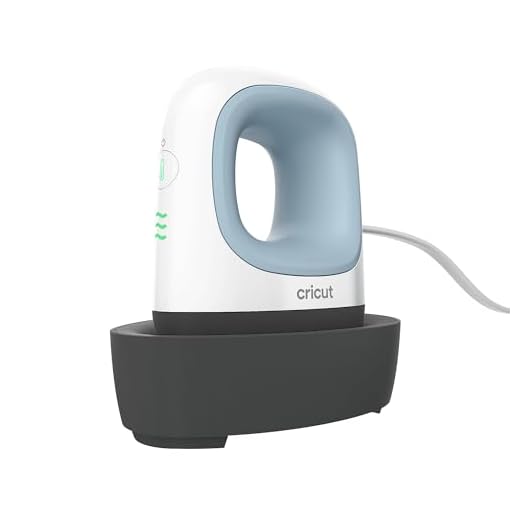

Recommended kit: heat press or hand-held flat heat tool, thin pressing cloth, cardboard insert, sewing needle size 90/14 (or 100/16 for heavy webbing), bonded polyester or nylon thread, small scissors, fabric glue for edge sealing. Always test on a scrap of the same fabric and emblem backing for 5–10 seconds to confirm temperature and dwell time.

Preparation: clean the surface of dirt and oils; preheat the target area for 3–5 seconds to remove moisture and reduce trapped steam. Center the emblem, use heat-resistant tape or low-tack masking tape to hold curved or small motifs in place. Place the pressing cloth directly over the backing to prevent adhesive shine or scorching; apply pressure from the center outward to avoid bubbles.

When the surface is heavy or multi-layered (padded straps, thick seams), press in 2–3 overlapping holds of 15–20 seconds rather than one long application. For delicate synthetics keep temperature and contact time lower (approx. 110–120°C / 230–248°F) and use a single quick press; if melting or gloss appears, stop immediately and test a lower setting.

Durability boost: after the adhesive cools, reinforce the perimeter with a narrow whipstitch or lockstitch using bonded polyester thread; stitch spacing 2.5–3.5 mm for medium fabrics, 3.5–4.5 mm for heavy fabrics. For rapid edge lift, apply a thin bead of clear fabric adhesive under the lifting edge and clamp until set.

Care and post-application rules: wait 24 hours before washing; machine wash cold (≤30°C / 86°F) inside-out on a gentle cycle; avoid high-heat tumble drying – air dry or tumble low below 60°C (140°F). If edges begin to loosen after repeated laundering, refresh with a short reheat (10–15 seconds) under a pressing cloth or add sewn reinforcement.

Heat-Adhering an Embroidered Emblem to a Daypack

Set the appliance to 160–170°C (320–338°F) and press the heat-activated applique through a thin cotton cloth with firm, steady pressure for 20–30 seconds.

Tools & recommended settings

- Heat source: household pressing appliance or travel press (no steam). For delicate synthetics use 120–140°C (248–284°F).

- Barrier: thin cotton cloth, parchment paper, or a clean tea towel.

- Fasteners: low-tack masking tape or fabric clips to hold position.

- Reinforcement: needle and polyester thread, fabric glue (solvent-free) as backup.

- Optional: small metal ruler or wooden block to apply extra localized pressure (avoid direct contact between metal and adhesive).

Step-by-step application

- Surface prep: clean with rubbing alcohol; remove dirt, oils, and waterproofing residue. Dry completely.

- Position: place emblem where desired; secure edges with tape so it cannot shift during pressing.

- Test spot: if fabric is synthetic or coated, test a scrap at the chosen temp for 5–10 seconds to check for melting or finish damage.

- Preheat area: briefly (3–5 seconds) touch the appliance to the placement area to remove trapped air and flatten seams.

- Press: cover applique with the barrier cloth, apply firm pressure for 20–30 seconds at 160–170°C (or 12–20 seconds at 170°C for thicker adhesives). For nylon/polyester use 120–140°C and hold 25–35 seconds with steady pressure.

- Cool and peel: allow to cool for 90–120 seconds, then peel backing at a 45° angle. If edges lift, replace barrier and repress for 10–15 seconds.

- Secure edges: for curved, padded, or high-stress zones stitch a 2–3 mm running or blanket stitch around the perimeter; use glue under lifted corners for extra hold.

Troubleshooting:

- Adhesive won’t set: raise temperature by 10–15°C and press longer, or add a few hand stitches through the emblem base.

- Fabric surface melted or sheen changed: lower temp, use a thicker barrier, or avoid heat method on that material; stitch or use contact adhesive instead.

- Edges peel after washing: hand-stitch perimeter and launder inside out on cold; air-dry to prolong bond.

- Uneven bond on seams/curves: flatten with temporary backing (cardboard inserted into the main compartment) and apply targeted pressing with a small block.

Check the bag fabric’s heat tolerance and lining

Set the temperature conservatively and test first: aim for 110–150°C (230–300°F) for most synthetics, 150–200°C (300–390°F) for plain cotton or canvas; avoid sustained heat above 200°C on coated, laminated or faux-leather surfaces.

Fabric temperature guideline

- Nylon / nylon blends: 110–140°C (230–284°F); short pulses 5–8 seconds; risk–shiny marks, melting of filaments.

- Polyester: 130–150°C (266–302°F); 6–10 seconds; risk–surface gloss and weakening of fibers if overheated.

- Canvas / cotton: 170–200°C (338–392°F); 10–15 seconds; cotton tolerates higher heat but shrinkage and color loss possible.

- Coated fabrics (PU/TPU/PU laminate): max 120–140°C (248–284°F); very short contact; risk–delamination, bubbling, tacky residue.

- Faux leather / vinyl / PVC: avoid direct heat; do not exceed 100–120°C (212–248°F) if absolutely necessary; prefer mechanical attachment or low-temp adhesives.

- Polypropylene webbing: avoid heat (melting ~160–170°C / 320–338°F); use sewing or non-thermal bonding.

- Metal hardware and metal-toothed zippers: withstand heat but plastic teeth and coated sliders melt at lower temps–keep heat away from trim.

Inspection and test procedure

- Read the care label for fiber content and any “do not” symbols.

- Check inside: foam padding, waterproof membranes, welded seam tape or glued linings are heat-sensitive; remove or avoid heating areas over them.

- Perform a spot test on an inconspicuous panel: cover with a thin cotton cloth or parchment, apply heat at target temperature for 5–10 seconds, then inspect for discoloration, shine, softening, bubbling or odor.

- If the lining delaminates, becomes gummy or the foam compresses, stop and use a non-thermal method (stitching or fabric adhesive designed for coated textiles).

- For straps and webbing, attach only by sewing; do not route heat across buckles, welded seams or taped joins.

Protective measures: always use a clean cotton press cloth or baking parchment between the hot surface and material; apply medium pressure in short bursts rather than a single long application; work on a firm, flat surface. For product-specific examples and alternative attachment ideas for soft goods, see best active winter sweaters for small breed dogs.

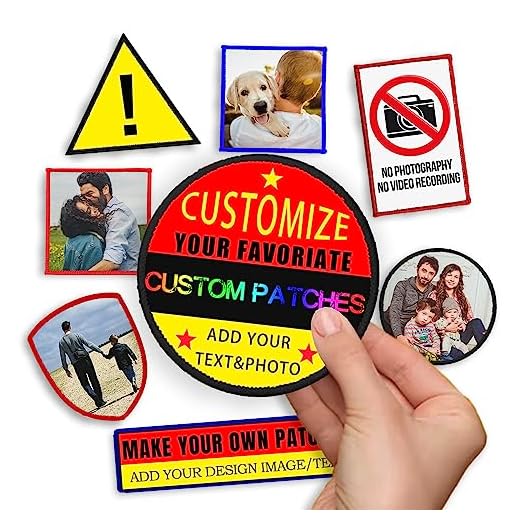

Select compatible backing and adhesive type

For heavy cotton, canvas or denim packs choose an embroidered emblem with a fusible-film (EVA/hot‑melt) backing and finish with a narrow running stitch (2–3 mm from the edge); typical activation parameters for these films are 120–150°C (248–302°F) for 10–15 seconds under firm pressure, peel warm. If the item will see high abrasion or carry weight, prefer sewn perimeter reinforcement regardless of adhesive.

Backing material choices

Embroidered with merrowed edge – best for durable, washable applications; medium-thickness stabilizer plus fusible film for adhesion. Woven twill or printed heat-seal decals – low-profile, good for smooth fabrics. PVC/TPU die-cut badges – thin heat-seal layer works on natural fibers but performs poorly on coated synthetics without primer. Fusible web (pelon-type) – suitable for lightweight woven fabrics only; avoids bulky backing but has lower shear strength. Pressure-sensitive liners – use for temporary or removable labels; expect limited wash resistance.

Adhesive chemistries and substrate matching

Acrylic-based adhesives – high water and UV resistance, stable to ~80–100°C; preferred for washable textiles and polyester blends. EVA/hot‑melt fusibles – fast bonding to cotton and cotton blends, moderate wash durability; soften above ~60–80°C. Solvent-based contact cements (Barge, neoprene) – excellent for leather, rubberized or PVC-coated surfaces; requires solvent-compatible substrate and good ventilation. Polyurethane adhesives – flexible, strong bond to PU/TPU coatings but often require a primer and longer cure time. Hot-glue gun adhesives – acceptable for cosmetic attachment or low-stress use, poor machine-wash and heat resistance. For coated or laminated fabrics and high-stress areas use mechanical stitching or bar-tacks in addition to adhesive; for leather or vinyl, prioritize solvent or urethane systems over fusible films.

Selection checklist: match backing thickness and edge finish to fabric texture; choose adhesive chemistry for the substrate coating (acrylic for uncoated/washable, solvent/urethane for coated/technical fabrics); decide between permanent (acrylic/urethane/solvent) and removable (pressure-sensitive) bonds; add sewing when load, abrasion or frequent laundering is expected.

Clean, dry and flatten the surface before attaching a heat-activated emblem

Wipe the target area with 70% isopropyl alcohol on a lint-free microfiber cloth and allow 10–15 minutes to air-dry at 20–22°C; surface should be cool and free of tack before any heat activation.

For oil or grease spots: mix 1 teaspoon neutral liquid detergent per 250 ml warm water, work gently with a soft-bristled brush, blot with an absorbent towel, rinse sparingly, then repeat the alcohol wipe and wait 15–20 minutes. For adhesive or sticky residues use a cotton swab with a citrus-based solvent or rubbing alcohol, spot-test out of sight for 30 seconds first, blot until transfer stops, then dry for 1–2 hours.

Flattening and firm backing

Insert a rigid support inside the pack cavity – 4–6 mm plywood, a plastic cutting board, or layered cardboard covered with a clean cotton cloth – positioned so the fabric lays flat without wrinkles. Smooth from the center toward edges with a soft roller or the flat of your palm; apply low-residue painter’s tape at the edges to hold tension while drying. For curved seams, use a small seam roller and make 2–3 light passes to remove air pockets.

Tools, supplies and timing

Essential items: 70% isopropyl alcohol, microfiber cloths, soft-bristled brush, neutral detergent, painter’s tape, flat board (min 4 mm), seam or paint roller, hair dryer (low setting) for spot-drying. Confirm dryness by touch – fabric must not feel cool or damp.

| Contaminant | Cleaning agent | Application | Recommended dry time |

|---|---|---|---|

| Light dirt | Warm water + neutral detergent | Wipe and blot | 15–20 minutes (air dry) |

| Oil / grease | Dish detergent or degreaser | Gently agitate, blot, rinse | 30–60 minutes |

| Body oils / sweat | 70% isopropyl alcohol | Thorough wipe | 10–15 minutes |

| Sticky residue / adhesive | Citrus solvent or rubbing alcohol (spot-test) | Spot treat, blot | 1–2 hours |

| Wet or soaked fabric | Air dry; low hair dryer from 30 cm | Support inside to keep flat | 1–3 hours depending on layer thickness |

Set temperature and disable steam for heat-activated adhesives

Set the heat tool to specific temperature ranges and switch steam off before applying any heat-activated adhesive: Cotton/canvas/denim: 350°F (177°C); Polyester/nylon blends: 300–320°F (150–160°C); Delicate synthetics: 260–290°F (127–143°C); Leather/vinyl (only if manufacturer permits): 240–275°F (116–135°C).

Disable the steam function completely. Moisture lowers surface temperature, prevents the adhesive reaching its melt point and can produce bubbling, adhesive migration or white residue on the heated plate. Use strictly dry heat for a consistent bond.

Apply firm, even pressure for an initial dwell time: 10–15 seconds for synthetics, 15–20 seconds for cottons and heavy fabrics. If bond is incomplete, add repeated 5–10 second dry pulses rather than increasing temperature beyond the recommended range.

Always protect the visible surface with a thin cotton pressing cloth or a Teflon release sheet to prevent scorching and glossy marks. Place a heat-resistant pad inside or under the item to stop adhesive from seeping through to inner layers or linings.

Perform a test on a scrap of the same materials: set temperature, disable steam, press for the target time, allow full cooling, then peel the carrier according to adhesive type (cold-peel vs hot-peel). If the test fails, lower temperature and increase time for synthetics, or reduce time for heat-sensitive materials.

Use a calibrated infrared thermometer or the appliance’s displayed temperature for verification; surface readings can differ from set values by ±10–20°F (±5–10°C). Adjust accordingly rather than relying on presets alone.

Position emblem, cover with a pressing cloth and apply steady pressure

Place the applique exactly where you want it; align edges using a ruler and secure with low‑tack heat‑resistant tape or very small pins through the garment edge only. Support the area with a firm backing (thin wooden board, folded towel or pressing ham) to prevent movement and fabric distortion while applying pressure.

Cover the motif with a dry 100% cotton cloth or a sheet of uncoated parchment paper to protect both the surface and the tool’s flat face. Apply continuous, even downward force without sliding: for motifs ≤7 cm hold steady pressure for 15–20 seconds; 7–12 cm use 25–35 seconds; >12 cm work in 20–25 second overlapping passes across the design. Aim for roughly 3–5 kg (6–11 lb) of sustained force over the contact area – use the weight of the tool plus firm hand pressure, or press with a calibrated household press if available.

Do not rock or scrub; lift straight up when a cycle completes. Let the treated area cool undisturbed for 2–5 minutes before testing adhesion by gently lifting a corner. If edges lift, re-cover and press an additional 10–15 seconds in the lifted sections only. For tools with a small contact face, press center-to-edge in sequential spots rather than dragging.

For projects mounted on a daypack intended for travel, check compatible luggage options at best luggage for family cruise. To protect a treated item from rain between trips, consider carrying a compact protective cover or umbrella such as this best umbrella for carrying an instrument.

Cool fully, test adhesion and reinforce edges with stitches or fabric glue for heavy use

Leave the applied emblem flat and undisturbed for 45–60 minutes; for heavy synthetics (Cordura, ballistic nylon) extend to 75–90 minutes to allow the adhesive to set and the substrate to return to ambient temperature.

Perform three quick checks before regular use: 1) nail-lift: try to lift a corner with your fingernail – no movement indicates initial bond; 2) tape-peel: press a 5 cm strip of strong tape (3M-type) onto the center, then pull sharply at 180° – any delamination means reinforcement is needed; 3) wash-sample: run one cold (30°C/86°F) gentle cycle and air-dry, or hand-wash the area, then inspect for lifting. If any edge separates, reinforce before additional laundering.

For adhesive reinforcement, choose a solvent- or polymer-based fabric adhesive such as Fabri-Tac, Tear Mender, or a neoprene contact cement designed for textiles. Apply a thin, even bead 1–2 mm from the applique edge (avoid squeezing into the visible face), press for 10–30 seconds, then clamp flat with binder clips or a weighted board for 2 hours; allow full cure 24–48 hours before heavy use or washing.

For sewn reinforcement with a machine: use a denim/jeans needle 90–100 (or universal 80–90 for medium weight), polyester or nylon thread (40–50 wt), stitch length 2–2.5 mm, and set the seam 1.5–3 mm from the applique edge. Straight topstitching or a narrow zigzag (2 mm width) both work; start and finish with a short backstitch or lock stitch. For handwork: use waxed polyester thread or heavy cotton thread, a sharp crewel/embroidery needle, blanket or overcast stitch spaced 3–4 mm (6–8 stitches per inch) around the perimeter; finish with three locking stitches at start/end.

Best practice for high-stress gear: combine methods – secure the emblem with adhesive first to eliminate movement, then stitch the perimeter. Add an internal reinforcement patch (lightweight woven interfacing or a scrap of similar fabric) 3–5 cm larger than the emblem, either glued or stitched, to distribute load. Seal raw edges with a small amount of clear fray-seal (e.g., Fray Check) and let dry 10–15 minutes to prevent fraying under heavy wear.

FAQ:

Can I iron a patch onto a nylon or polyester backpack without damaging the fabric?

Yes, you can in many cases, but fabrics with synthetic fibers or water-repellent coatings need a gentler approach. Check the care label on the backpack first. If it allows low heat ironing, place the backpack on a flat, heat-safe surface and smooth the area where the patch will go. Put the patch adhesive side down, cover it with a thin cotton cloth or parchment paper, and set the iron to the lowest setting for synthetics (often labeled “synthetic” or a low temperature around 110–150°C / 230–300°F). Use a dry press rather than steam, apply firm even pressure for 15–30 seconds, lift the iron and repeat if needed, then let the patch cool fully before testing adhesion. If the backpack has a shiny water-repellent finish, the glue may not bond; in that case stitch around the edge by hand or with a machine, or use a specialty adhesive designed for coated fabrics. If the backpack contains foam padding under the fabric, press from the inside or place a flat board behind the area so pressure transfers evenly. Test on a small hidden spot or a scrap first to make sure heat and pressure won’t distort the material.

My iron-on patch started peeling after a few washes. How can I repair it and make it stay attached longer?

Peeling after washing is common when the bond was incomplete or the patch faces repeated heat and agitation. For a quick repair, press the patch again: clean and dry the area, cover the patch with a pressing cloth, and apply firm heat and pressure with an iron for a bit longer than the first time. Follow the patch maker’s guidance on whether to peel the backing hot or cold before pressing. For a stronger fix, add stitching around the perimeter—use a needle and matching thread and sew small, even stitches or a whipstitch; a sewing machine with a zigzag stitch gives the best durability for heavy use. If you prefer glue, apply a thin bead of washable fabric adhesive around the edges only and press until set; choose a product labeled washable and flexible. To prevent future lifting during laundering, wash the backpack gently: turn it inside out, use cold water on a gentle cycle or hand wash, and air dry rather than tumble drying. Finally, if the backpack has a water-repellent coating or a slick synthetic, skip relying on the adhesive alone and combine stitching with glue for long-term hold.