Recommendation: Use heavy cotton twill 10–12 oz or 600D polyester; cut main panels at 40×45 cm (16″×18″), a bottom strip 40×10 cm (16″×4″) and leave a 1.5 cm (5/8″) seam allowance. Select a 5–6 mm nylon cord (total length 3–3.5 m / 10–12 ft for a continuous loop), install 6–8 mm grommets, and sew with a 90/14 or 100/16 needle using bonded polyester thread at a stitch length of 3.0–3.5 mm.

Cut two identical body panels and a bottom panel, press raw edges, then sew panels right sides together with the 1.5 cm allowance. Fold the top edge down to create a drawcord channel 3 cm (1 1/8″) wide; topstitch 0.5 cm from the folded edge to stabilize the channel. For the bottom join, align the bottom strip centered on the panel width and stitch with a double row where the base meets the body to distribute load.

Reinforce grommet positions with interfacing or a leather patch behind each hole; place grommets 3–4 cm (1¼″–1½″) below the top fold and space them 6–8 cm (2½″–3″) apart. Use bar tacks (8–10 short stitches) at both top-corner stress points and a box-X stitch (25×25 mm) for any webbing strap attachments. If adding shoulder straps from 25–30 mm (1″–1¼″) nylon webbing, cut lengths of 60–75 cm (24″–30″) and finish ends by folding and stitching to prevent fraying.

For a stiffer base, insert a 2–3 mm closed-cell foam or a 2–3 mm leather panel cut 36×8 cm (14¼″×3¼″) before closing the bottom seam. Use clips instead of pins on heavy fabric, and test feed the cord through the channel with a blunt bodkin or a large safety pin. Final checks: tug each seam under load, trim thread tails to 4–5 mm, and add small washers behind grommets for long-term wear resistance.

Select fabric, lining, and precise dimensions for your size

Use 10–12 oz waxed cotton (≈340–410 g/m²) or 500–600D Cordura for the shell; pair with 200–380T polyester taffeta or 210D ripstop for the lining.

Recommended materials & hardware

- Outer fabrics:

- Waxed cotton 10–12 oz – water resistance, soft break-in.

- 500–600D nylon (Cordura) – abrasion resistance, lighter than 1000D.

- Light option: 8–10 oz cotton canvas or 300D polyester for day-use sacks.

- Linings:

- 200–380T polyester taffeta (PU-coated variant for water shedding).

- 210D ripstop for durability with minimal bulk.

- Quilting cotton (100–150 g/m²) only for casual/non-wet use.

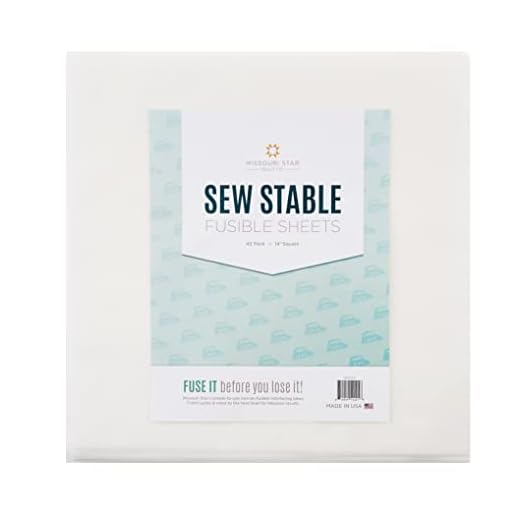

- Interfacing & reinforcement:

- Bag base: 2–3 mm closed-cell foam or firm plastic insert cut to base size.

- Straps: 1–2 layers of 3–4 mm foam or 6–8 mm webbing + sew-in heavy interfacing (80–120 g/m²).

- Top casing: double-layer folded 9 mm–15 mm total seam allowance; add sew-in 1 mm stabilizer if fabric is floppy.

- Hardware and notions:

- Zippers: YKK #3 or #5 for pockets; coil for low-bulk.

- Grommets/eyelets: 6–8 mm inner hole for 6–8 mm cord.

- Cord: braided polyester/nylon 6–8 mm; cord length 120–140 cm for looped shoulder carry.

- Thread: bonded nylon or polyester size T70 or 30–40 wt; needles 90/14 (500–600D) or 100/16 (heavier canvas).

- Sewing settings: stitch length 3.0–3.5 mm on heavy fabrics; use triple or reinforced seams at stress points; topstitch 4–6 mm from folded edges for stability.

Cutting dimensions and allowances (Small / Medium / Large)

All pattern pieces below include recommended seam allowances. If you prefer imperial, 1 cm ≈ 3/8″.

- Overall body panel (height × width):

- Small: 36 cm × 26 cm (final height ~34 cm after 1 cm top and bottom seams and rolled hem).

- Medium: 42 cm × 30 cm.

- Large: 48 cm × 34 cm.

- Base depth (boxed corner square = desired depth):

- Small depth 8 cm → cut 8×8 cm corner squares.

- Medium depth 12 cm → cut 12×12 cm squares.

- Large depth 14 cm → cut 14×14 cm squares.

- Base panel (optional flat base):

- Cut to width = body width − 2 × seam allowance; length = chosen depth.

- Example medium flat base: 30 cm × 12 cm (add 1 cm seam allowance each long edge when sewing to sides).

- Top casing for drawcord:

- Cut a strip 9 cm tall for a 4 cm finished casing (folded twice); length = body circumference + 2 cm overlap for seam.

- Seam allowance for casing: 1.5 cm at each short edge for finishing.

- Internal zip pocket (recommended placement at 10–12 cm down from top):

- Medium pocket cut: 20 cm × 13 cm (allow 1 cm seam allowance all around; zipper length 20 cm).

- External front pocket:

- Medium front pouch: 26 cm × 14 cm; top edge reinforced with 1.5 cm double-folded facing; zipper height allowance 2 cm.

- Webbing and strap lengths:

- Flat shoulder straps (adjustable): 80–110 cm length each, 25–38 mm width.

- Single sling: 120–140 cm × 25–38 mm.

- Reinforcement webbing for side seams: 25–30 mm, run from base to top + 10 cm overlap for stitching.

- Grommet placement:

- Two grommets spaced 6–8 cm apart centered on the front; top edge set 1.5–2 cm below top hem; distance from side seams 2–3 cm.

Use the linked resource for alternative carry styles and packing ideas: best waist packs for travel.

Draft pattern and mark cutting layout with seam allowances and notches

Use a full-size paper master with these exact panel measurements for a finished drawstring pack of 15″ (38 cm) wide × 18″ (46 cm) high; add the specified allowances to the pattern before cutting.

Pattern pieces and allowances

Main body (cut 2): pattern rectangle 16.25″ (41.3 cm) wide × 19.625″ (49.8 cm) high – this includes 5/8″ (1.5 cm) side seams, 5/8″ bottom seam and 1″ (2.5 cm) top casing allowance. Mark grainline vertical; cut two mirror pieces.

Front pocket (cut 1 or 2): finished pocket 9″ × 6″ (23 × 15 cm). Pattern size 9.75″ × 6.75″ (add 3/8″ / 1 cm around). If using a pocket flap, add 3/4″ (2 cm) top hem and 3/8″ seam edges.

Straps (cut 2 or 4 as required): finished flat strap 1.5″ (3.8 cm) × 28″ (71 cm). Cut strips 3.25″ (8.3 cm) wide to allow 3/8″ (1 cm) seam and 1/4″ topstitch return; length as desired. For doubled webbing, cut bias binding if rounded corners are needed.

Lining panels (cut 2): same finished size as body but pattern = 15″ + (2×5/8″) by 18″ + (2×5/8″) = 16.25″ × 19.25″ (adjust if you omit top casing in lining). Use 5/8″ seam allowances around.

Notches, match points and boxed corners

Mark notches as small V-cuts 1/4″ (6 mm) deep at: top center of each body panel (for casing alignment), side seam midpoint (for pocket placement) and strap attachment points 2″ (5 cm) in from each side edge and 2″ (5 cm) down from top fold. Number matching notches with chalk or tailor’s tacks on both layers.

For boxed bottom corners: draw a 2″ (5 cm) square at each bottom corner of the finished-panel line. Mark the fold line across that square and transfer this to both shell and lining pieces so boxed corners align when sewn. Add a small notch at the corner of the square to align seams precisely.

Transfer all markings with a washable fabric marker, tracing wheel on interfacing or tailor’s tacks; mark grommet/casing centers 2″ (5 cm) from vertical edges and 3/8″ (1 cm) below the top fold line. Use a 1/2″ (1.3 cm) notch at pocket center and pocket top corners to align pocket placement exactly.

For cutting layout on 44″ (112 cm) wide fabric: fold selvage-to-selvage and stack two layers. Place the two body panels nested along the fold grainline to save fabric (panels placed parallel to selvedge), put pocket pieces on single layer along remaining width, and place straps on the bias strip or along lengthwise grain depending on desired stretch. On wider 54″ fabric you can place both body panels side-by-side without folding. If using directional print, orient grainline arrows consistently.

Fuse interfacing pieces slightly smaller than outer pocket and strap pattern by 1/8″ (3 mm) inside seamlines to avoid stiff edges. Mark interfacing placement on the pattern and transfer with chalk after fusing.

For an unrelated local diversion, see best aquarium in ohio.

Cut pieces and prepare edges: interfacing, seam finishes, and reinforcement

Cut shell panels with a 5/8″ (15 mm) seam allowance; use 1/2″ (12 mm) for straps and webbing attachment pieces. Mark all notches, pocket placement, and hardware centers with chalk or a fabric pen; transfer interface placement to wrong side before fusing or sewing.

Interfacing choices and placement

Select by stiffness: lightweight fusible (40–90 gsm) for linings and pocket bags; medium fusible (90–200 gsm) for side panels and flap faces; heavy/stiff stabilizer (200–400+ gsm or structured Peltex/medium plastic canvas) for base and pocket bottoms. For straps, either use sew-in cotton canvas strip or fuse a 200–300 gsm woven interfacing and topstitch after folding.

Application tips: test fuse on a scrap at low-to-medium iron setting matching fabric content; use a press cloth for coated or heat-sensitive outer fabrics. For synthetic shells and waterproof coatings avoid high heat–use sew-in interfacing or adhesive spray (basting spray) if fusible won’t bond. Fuse interfacing to full panel faces where structure is required; use narrow 20–30 mm fuse strips at pocket openings and zipper tapes.

Seam finishes and edge preparation

Seam allowances: standard 5/8″ (15 mm) for main seams, reduce to 3/8″ (10 mm) or trim to 1/4″ (6 mm) on curved joins to lessen bulk before turning. Stay-stitch curved edges 3–4 mm from the raw edge.

Finish methods: use a serger (3- or 4-thread) for outer shell seams; if no serger, trim to 6 mm and zigzag (3 mm width, 2.5 mm length) the raw edge. For high-strength joins use flat-felled seams: sew with a 5/8″ allowance, trim one side to 3–4 mm, fold and topstitch with a 4–6 mm seam cover. Avoid French seams on heavy fabrics–reserve them for light lining pieces only.

Topstitching: use 3.0–3.5 mm stitch length for visible topstitch lines and 2.5 mm for structural seams; place topstitch 3–8 mm from folded edge depending on aesthetic. Use heavy polyester or bonded nylon thread for topstitching and structural seams; for visible decorative stitches choose 40 wt cotton/poly for contrast.

Curve and corner handling: clip concave curves every 3–5 mm; notch convex curves to 3–4 mm. Trim seam corners to a 3 mm diagonal point before turning and press with a point presser or blunt tool to square corners without piercing fabric.

Reinforcement techniques: bartack or box-X at all strap anchors and top stress points. Standard bartack: 12–15 mm long, 7–9 dense zigzag stitches; box-X: 25 mm square, sew the box then an X across it with 2.5–3.0 mm stitch length. Place rivets 8–12 mm from the edge where webbing meets shell; pre-punch holes and set with a hand rivet setter or press. For D-rings or sliders, stitch a doubled webbing tab and topstitch a 25 mm box-X; add a drop of clear fray seal on cut webbing ends.

Base insert and pocket reinforcement: cut a removable base stiffener (3–5 mm plastic, heavy Peltex, or laminated board) to 1–2 mm less than inner base dimensions so it drops in easily. Fuse or sew a 30 mm wide interfacing strip behind pocket openings and zipper plackets; stitch a reinforcement bar (25–30 mm long, 3–4 rows of stitching) at pocket mouths.

Waterproof seams and coated fabric notes: stitch using a longer needle (100/16) and bonded polyester thread; taping seam allowances with seam-seal tape on the wrong side before adding lining prevents leakage. For PVC/coated fabrics use a walking foot, reduce presser foot pressure, and avoid fusible interfacing that melts–opt for sew-in stabilizers and adhesive tape.

Quick storage and hanging tip: for drying or airing finished gear, consider light, compact options similar to an outdoor line – see best umbrella style clothesline.

Sew bag body and form boxed corners for stability

Use a 1/2″ (12 mm) seam allowance on vertical and bottom seams; stitch with polyester thread, 2.5 mm stitch length, and a universal 90/14 needle for woven canvases or 100/16 for heavy canvas or cordura.

Sew the side seams with pieces right sides together, backstitch 6–8 mm at each end, press seams open for reduced bulk or press toward the back panel for greater durability. Trim seam allowances to 6–8 mm where they meet bulky intersections before forming the base.

Determine boxed-corner depth from desired finished base width using this formula: box depth = finished base width ÷ 2. Example: for a 6″ finished base width, mark 3″ (75 mm) from the corner along both the bottom and side raw edges.

With the bag still inside out, flatten each corner so the side seam aligns with the bottom seam. Using a ruler, draw a perpendicular line across the corner at the box depth mark. Stitch directly on that line across the corner, sewing from edge to edge. Use 2.5–3.0 mm stitch length and backstitch 4–6 mm at start and finish.

Trim the excess triangle leaving a 6 mm (1/4″) seam allowance; trim carefully without cutting the stitch line. For heavyweight fabrics, grade the trimmed seam to 4 mm, or clip the corners into a small curve to reduce bulk before turning.

Turn the bag right side out and press each boxed corner flat so the seam runs neatly along the center of the box. Topstitch 3 mm (1/8″) from the outer seam across the boxed corner to lock shape; use a longer stitch length (3.0–3.5 mm) for visible decorative topstitching.

Reinforce high-stress corners with a 7–10 mm bar tack or a dense zigzag over the topstitched line, using heavy nylon thread. If adding a fabric or webbing base patch, install it before boxing corners to keep layers even and reduce shifting.

| Element | Recommendation | Notes |

| Seam allowance | 1/2″ (12 mm) | Use consistent allowance for pattern accuracy |

| Stitch length (seams) | 2.5 mm | Standard strength; reduce for very heavy fabrics |

| Stitch length (topstitch) | 3.0–3.5 mm | Cleaner visible stitchline |

| Box depth examples | 2″ (50 mm) → 4″ base; 3″ (75 mm) → 6″ base | Choose depth based on intended carry capacity |

| Trim allowance after sewing | 6 mm (1/4″) | Leave enough to finish seams or serge |

Create drawstring casing, install grommets or cord locks, and thread cord

For a 4–8 mm round cord, construct a finished casing 18–22 mm (3/4″–7/8″) wide: turn the raw edge 6 mm (1/4″) to the wrong side, press, then fold so the folded edge sits 18–22 mm from the top; topstitch 3 mm (1/8″) from the inner fold with 2.5–3 mm stitch length.

Sew the casing with a 12–15 mm (1/2″–5/8″) allowance below the top fold to leave a smooth channel; backstitch 6–8 mm at the start and end of the topstitch line. For heavier fabrics increase topstitch length to 3 mm and use a walking foot or teflon presser foot to prevent skipped stitches.

Reinforce grommet/exit points with a fusible woven interfacing (light to medium weight) or a sewn patch. Use a circular patch 30–40 mm (1 1/4″–1 5/8″) or a square 40×40 mm (1 5/8″×1 5/8″) placed on the wrong side, centered on planned hole. Stitch a 6 mm (1/4″) box with an X over the patch after grommeting for extra abrasion resistance.

Place metal eyelets/grommets so their centers are 20–25 mm (3/4″–1″) from the side seams and 5–8 mm (1/8″–5/16″) below the bottom edge of the casing channel (so the cord exits under the casing). Choose grommet inner diameters relative to cord: 3–5 mm cord → 6–8 mm ID; 5–8 mm cord or thin braided paracord → 8–10 mm ID. Test punch size and seating on scrap material before installing on the bag body.

Tools and hardware: sharp hollow punch or revolving leather punch sized 1–2 mm smaller than grommet barrel, grommet setting tool or hand press, rubber anvil or steel base, and mallet/press. For light fabrics use washer-style grommets with larger flange; for heavy nylon or canvas use reinforced two-piece eyelets and set with a grommet press. Always set grommets perpendicular to the fabric surface and check alignment with the opposite piece before crimping.

For cord locks and stops: slide the cord through the spring barrel or two-hole toggle before knotting. Melt synthetic cord ends with a lighter to prevent fray (short bursts; press quickly against a non-flammable surface), or add a small knot or crimp sleeve and cover with heat-shrink tubing. Metal crimps require pliers and a drop of fabric glue or a flattened fold to secure.

Recommended cord lengths: single continuous loop = (bag height × 2) + (desired strap drop × 2) + 30–40 cm (12–16″). Example: 40 cm tall bag with 45 cm strap drop → (40×2)+(45×2)+30 = 200 cm (~79″). Two independent cords = bag height + strap drop + 15–20 cm each. Use a safety pin or bodkin to feed the cord; tape the end or melt it to stiffen for easier threading. After threading, tie secure knots (double overhand or figure-eight) and hide knots inside cord locks or under a small fabric tab; finish exit points with a 6–8 mm bar tack on the inside of the casing to prevent fabric wear.