Recommendation: remove the damaged tape completely, measure the opening length to within ±3 mm, then fit a coil tape 2–4 mm longer than the seam allowance. Use a separating slider for main compartments and a non-separating slider for pocket openings. Choose coil (nylon) for lightweight packs, molded (plastic) teeth for heavy-load bags; size #3 for light daypacks, #5 for general purpose, #10 for heavy gear. Match tape width to the original hem or flange to avoid puckering.

Tools & consumables: seam ripper, heavy-duty polyester thread (Tex 70/90 or bonded nylon 40–60 wt), size 90/14 or 100/16 universal/microtex needle for machines, curved upholstery needle for hand sewing, long-nose pliers, crimping pliers for metal stops, lighter for synthetic tape ends, pins/clips, ruler and tailor’s chalk. Machine settings: straight stitch 3.0–3.5 mm length, presser foot pressure reduced for bulky seams, walking foot recommended. Hand stitches: double backstitch or box-stitch at terminals, 3–4 mm stitch spacing using waxed thread for abrasion resistance.

Quick checks and tips: test the slider through 10 full open/close cycles before final topstitching; lubricate stubborn sliders with a dry bar soap or beeswax (avoid oils on water-resistant coatings). If teeth are missing over >1 cm or the tape is sewn under bound seams, opt for full tape swap rather than patching. Use metal crimp stops or bartacks at both ends and seal synthetic tape cuts with a brief flame to prevent fray. For waterproof-lined or leather packs consult a professional cobbler when seams are sealed, taped, or glued – these require specialty tools and heat-sealing to restore water resistance.

Install a new coil slider on a daypack

Match coil type and tooth size to the original: nylon coil #5 for 10–25 L daypacks, nylon coil #8 for 25–45 L, and metal tooth #10 or larger for heavy load / expedition packs; choose an auto-lock slider for single-pull openings and a non-lock slider for dual-pull systems.

Tools & materials

Use a heavy-gauge seam ripper, flat-nose and needle-nose pliers, a sharp curved upholstery needle (for hand work) or a 100/16–110/18 machine needle (for power sewing), bonded polyester or nylon thread (Tex 40–70), replacement coil tape cut 2–4 cm longer than original, new metal or molded stops, slider matched to coil width, beeswax or paraffin for lubrication, and clamps or sewing clips.

| Item | Spec / size | Qty | Est. cost (USD) | Purpose |

|---|---|---|---|---|

| Seam ripper | stainless, sharp | 1 | 3–10 | Remove stitches without cutting fabric |

| Slider | matches coil #5, #8, or #10 | 1–2 | 2–8 | Closure replacement |

| Bonded thread | polyester/nylon Tex 40–70 | 1 spool | 4–12 | Durable seam repair |

| Stops | metal crimp or molded | 2 | 1–4 | Prevent slider escape |

| Needle | curved #18 or machine 100/16–110/18 | 1–2 | 1–6 | Pierce heavy fabric |

| Lubricant | beeswax / paraffin | small | 1–5 | Smooth slider action |

| Total time | simple front pocket | 30–45 min | ||

| Total time | main compartment, sewn-in stops | 60–120 min |

Step sequence and technical tips

1) Measure existing coil pitch: count teeth per cm or note manufacturer number stamped on tape. Use an identical coil profile or slider will jam. 2) Remove nearby stitching with the seam ripper only as far as needed to expose the tape ends; preserve original fabric reinforcements and any hem allowances. 3) Release old slider by prying open the top stop with pliers; for nylon coil, apply a small amount of lubricant to ease removal. 4) Slide new slider onto one tape rail first, then feed second rail; align teeth at both ends before seating stops. 5) Fit new stops: crimp metal stops with flat-nose pliers at the original positions or use molded stops sized for the coil width; leave 3–5 mm clearance from tape edge to avoid fabric squeeze. 6) Sew repaired section using a 2.5–3.0 mm stitch length with two passes over high-stress areas; backstitch 6–8 mm at each end or hand-sew with locked stitches using a curved needle and double thread. 7) For nylon coil tape ends on synthetic fabric, melt a 2–3 mm bead with a lighter and press with pliers as an emergency stop (work in a ventilated area and avoid over-melting). 8) Test operation under load: open/close 20 full cycles, then apply normal pack weight to check for pull-out or snags.

Common failure causes and prevention: mismatch of coil profile, insufficient stop crimping, stitches set too close to the coil teeth (keep 4–6 mm seam allowance), or using thin thread–use bonded thread rated for outdoor gear. Typical total time: 30–120 minutes depending on access and whether a sewing machine is used.

Determine fastener length, tooth type (coil/metal/vislon) and compatible slider size

Measure the active chain from top stop to bottom stop along the tape; record both millimeters and inches, round up to the nearest 5 mm (0.2 in) and add 10–20 mm (0.4–0.8 in) allowance for installing new stops or trimming the tape.

Identify the tooth construction by visual and tactile cues: coil = continuous nylon/monofilament spiral, very flexible; metal = individual stamped or cast metal teeth (brass, aluminum, nickel); vislon/molded plastic = chunky, molded thermoplastic teeth with visible molding seams. Use a magnifier to confirm: coils have a smooth spiral edge, metals show distinct tooth profiles, vislon teeth interlock with a flat mating surface.

Measure tooth size with digital calipers across two opposing teeth. Common nominal sizes: #3 ≈ 3 mm, #4 ≈ 4 mm, #5 ≈ 5 mm, #8 ≈ 8 mm, #10 ≈ 10 mm. Many manufacturers label by number (#5 = 5 mm). For coils you can also measure chain width (outside-to-outside across the teeth) and match that mm value to the slider spec.

Select a slider that matches both tooth type and nominal size. Sliders are type-specific: coil sliders have a narrow internal channel for the spiral, metal sliders fit stamped metal teeth, vislon sliders have a deeper, wider channel for molded profiles. Match the slider number to the measured tooth number exactly; do not mix coil sliders with metal or vislon sliders. Separating sliders (box-and-pin) are required for open-end systems; closed-end systems use non-separating sliders.

Additional checks before ordering: bring a 3–5 cm sample of the tape with teeth or a close-up ruler photo to the supplier; confirm slider style (locking vs non-locking, single vs double pull) and material (brass/zinc/plastic) for compatibility with your application. If using coil tape, note it can be trimmed and fitted with new stops; metal and molded chains often require ordering the correct finished length or a factory-style end for reliable function.

Assess damage and remove the old tape without harming lining or fabric

Use a fine seam ripper, curved embroidery scissors and a pair of pointed tweezers; protect the lining with a thin piece of cardboard slid between outer shell and lining, then unpick from the lining side only. Leave 10–20 mm of the tape beyond each fabric edge if you plan to reuse the tape or want a clean anchor point for a new closure; label left/right and top/bottom with chalk or masking tape to preserve orientation.

Damage indicators and measurements

Inspect tape for fraying, delamination, burn marks, adhesive hardening, and holes in the seam allowance. Measure the damaged zone and add 15 mm per end for a safe margin; if the seam allowance has holes greater than 3 mm or the fabric weave is open more than 10% of original density, plan patching rather than reusing the tape. Note stitch configuration: single row at ~8–12 stitches per inch (3–5 mm between stitches) or double rows; record thread color and weight for later match.

Step-by-step safe removal

1) Slide a thin shield (cardboard or plastic shim) between lining and shell to prevent piercing the lining when cutting threads. Secure with clips every 50–70 mm. 2) From the lining side, cut 6–8 stitches at a time with the seam ripper at a shallow angle; never push blade toward the outer face. Pull the cut thread tails out with tweezers rather than cutting across the tape, which can nick fabric fibres. 3) If metal stops or end pieces are present, protect adjacent fabric with a strip of painter’s tape, then use flat-nose pliers to crimp and slide them off; for stubborn metal, snip off protruding portions with flush cutters, then pry gently. 4) Remove remaining stitching threads by pulling bobbin and top threads in the same direction to avoid tension damage to the seam allowance. 5) Lift any residual adhesive with a plastic scraper, then clean with a cotton swab and 70% isopropyl alcohol; test on a hidden area first. 6) Press the seam allowance flat with a low-temperature iron suitable for nylons/polyesters (approx. 110–120 °C) using a pressing cloth; avoid direct high heat on synthetics.

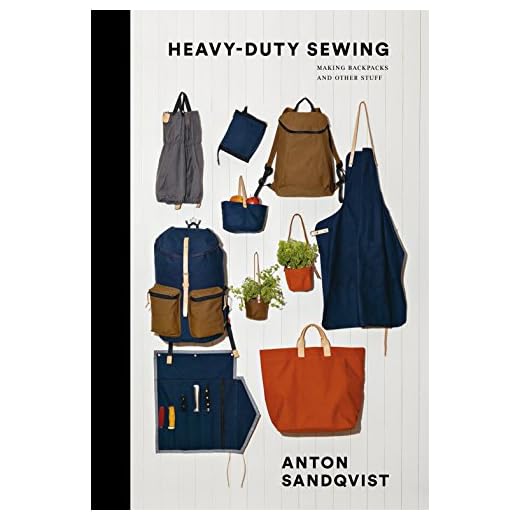

Keep all removed hardware and a 50 mm sample of the original tape for measurements and to match color/width when sourcing a new fastener; for reference on case layouts and compartment positioning consult best tech briefcase.

Prepare and reinforce the zip channel and fabric edges before fitting

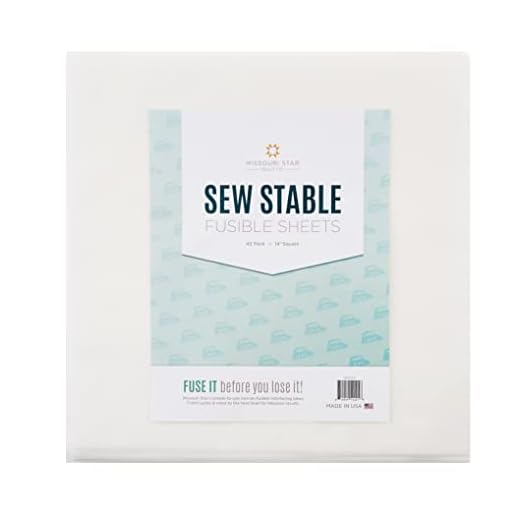

Fuse a 12–25 mm midweight fusible interfacing (approx. 90–160 g/m²) to both faces of the channel, overlapping the seam allowance by 3–5 mm to stabilize woven or ripstop fabrics.

Trim frayed edges to a clean line, then stay-stitch 3–4 mm from the cut with a 2.0–2.5 mm stitch length to prevent further runout; for slippery fabrics use a 3 mm wide zigzag at 2.5 mm length instead of straight stay-stitching.

Edge reinforcement options

Sew-in twill or nylon seam tape 10–15 mm wide applied under the channel provides high-strength support for loaded closures; stitch a single row 3–5 mm from the folded edge, then topstitch 2–3 mm from the edge. For very heavy fabrics (ballistic nylon, tarpaulin) add a folded leather or heavy nylon tab 20–30 mm wide at each end and either rivet or box-stitch it with 4 rows of 3.0 mm length stitches across the tab.

For light to medium fabrics, apply a thin line of water-soluble basting adhesive across the interfaced area to hold the tape or fastener in place during sewing; allow 10–20 seconds to tack before handling. Use a heat-activated seam sealant (fray-stop) on cut edges of synthetic fabrics–apply a single thin bead, let set 30–60 seconds, then trim any excess.

Sewing settings and hardware guidance

Use heavy polyester or bonded nylon thread (Tex 40–70 or upholstery grade). Needles: 90/14 for canvas/cordura, 100/16 for thick ballistic or coated textiles; leather needle only for genuine leather tabs. Machine stitch length for assembly: 2.5–3.0 mm; for topstitching: 3.0–3.5 mm. When locking the channel ends, perform a 5–7 pass bartack or sew a 12–15 mm box with an X inside; bartack width 8–10 mm.

Final checks: press the prepared channel with a press cloth at fabric-appropriate heat for 8–12 seconds per area, confirm both edges run parallel within 1–2 mm over the full length, and verify that reinforcement layers lie flat without puckering before fitting the new fastener tape.

Hand-sew the replacement closure: stitch type, spacing, anchoring points

Use bonded polyester or waxed nylon thread (heavy-duty; commercial sizes 69–92 or Tex ~70–150) with a heavy sharps or curved upholstery needle (#90/14 or similar) and sew a backstitch with 2.5–4 mm stitch spacing for normal pack fabrics; reduce to 2–3 mm for lightweight materials and increase to 4–6 mm for very coarse canvas.

Baste the tape temporarily with 4–6 mm running stitches (contrasting thread) through the tape and seam allowance only; this holds alignment while you sew the final seam and avoids catching the lining. Place basting stitches 3–5 mm from the tape edge so final stitches sit directly on the original stitch line.

Perform the backstitch like this: bring the needle up at point A, push it forward to point B (~3 mm), then bring it up at point C (~3 mm ahead of B) and insert back into B; repeat. Each stitch overlaps the previous hole, producing a continuous, load-bearing seam that behaves like machine lockstitch.

For high-load attachments (pocket openings, strap junctions), stitch two parallel rows 5–7 mm apart. Offset the stitches so the second row fills the gaps of the first: this doubles shear strength and reduces seam splay under load.

Anchor both ends with dense bar-tacks: fold tape and fabric layers together, then stitch 8–12 very short passes (1–2 mm) back and forth over a 10–15 mm length. For strap termination points use a 10×12 mm box with an X across it (4 passes per side of the X) rather than a single tack; this distributes stress across more substrate.

Keep needle entry 1.5–2 mm from the teeth line to avoid the teeth and to catch the reinforced edge of the tape; sew through both tape and the seam allowance of the outer fabric so stitches transfer load into the textile, not just the tape.

Finish by sewing four solid backstitches inside the tape, burying the knot between layers, and applying a drop of clear seam sealant to the knot and bar-tack heads. If sticky residue or stubborn grime remains on tape edges before installation, consult this resource: can dogs have red wine vinegar.

Sew a new zip with a machine: presser foot choice, stitch settings, and seam sequence

Use a narrow right/left zip foot for edge stitching, switch to an open-toe edge-stitch foot for visible topstitching, and fit a walking (even-feed) foot for multiple heavy layers or sticky synthetics; use a Teflon or roller foot on coated fabrics.

- Needle & thread

- Lightweight lining/coil tape: universal 80/12 or microtex 70; polyester 40–50wt thread.

- Medium-weight Cordura/pack fabric: universal 90/14; bonded polyester or nylon thread Tex 27–35 (≈40–50wt).

- Heavy-duty 1000D or multilayer seams: denim/jeans 100/16; bonded nylon Tex 35–69.

- Stitch type & length

- Straight stitch for attachment: 2.2–2.5 mm (≈10–12 spi) when sewing tape to fabric.

- Topstitching for appearance/strength: 3.0–3.5 mm (≈7–8 spi) with heavier thread; edgestitch at ~2.0 mm from tape edge.

- High-stress anchor: triple straight stitch or triple-stitch program at 2.2–2.5 mm over reinforcement points.

- Temporary basting: 4.0–5.0 mm long stitch, removed after final seams.

- Tension & presser adjustments

- Set thread tension to machine default (usually 3.5–4); reduce to 3.0–3.5 on bulky sections to prevent puckering.

- Increase presser foot pressure slightly for thin slippery tapes; reduce pressure for very thick stacks to let layers feed evenly.

- Prepare and baste

- Trim seam allowance of panels to 8–12 mm where tape will sit; interface with light fusible tape if fabric frays or is very thin.

- Align tape so teeth/coil sit 2.0 mm inside final edgestitch line; baste with 4.0 mm stitches 8–10 mm from edge to keep position while sewing.

- Machine attachment sequence

- Mount zip foot and stitch from top stop down toward bottom stop with straight stitch 2.2–2.5 mm, keeping needle centered relative to foot; backstitch 6–8 mm at start and end.

- Move slider away from the area to avoid needle contact; if the slider must cross the sewing line remove it beforehand or stop and re-route.

- Remove basting stitches only after both sides are sewn and topstitching is complete (unless basting obstructs access).

- Reinforcement and finishing

- At zipper ends use a bar tack or multiple short zigzags: zigzag width 5–6 mm, stitch length 0.6–0.8 mm, run back-and-forth 3–5 times, or use machine bar-tack function.

- Topstitch 3–6 mm from the tape edge depending on style; for heavy tape use 5–6 mm with heavier thread for visual balance and added strength.

- Trim seam allowances to 3–4 mm near topstitched area, grade layers, and press with low heat using a press cloth on synthetic fabrics.

- Bulky points & troubleshooting

- Skipping stitches over thick shoulders: switch to a larger needle (e.g., 100/16), use walking foot, slow machine speed, and reinforce with a second pass if needed.

- Puckering: lengthen stitch slightly, lower tension, or add a stabilizer under thin fabrics.

- If teeth/coil catch thread, move the needle position slightly away from the teeth or use a thinner thread for the first pass and heavier thread for the topstitch pass.

- Quality checks

- Pull test the final ends with a 10–15 kg load for pack-use items; if stitching stretches, add an additional bar tack or increase thread thickness.

- Verify slider travel along full length before closing seams; adjust end-stops to prevent slider from coming off under load.

Install or swap the slider, align teeth, and test smooth operation under load

Use a slider that matches the tooth pitch, feed both rows of teeth into the slider so the tapes run perfectly parallel, then lock the slider with a new stop or a multi-pass sewn bar-tack 6–8 mm above the slider before any stress testing.

-

Prepare and fit the slider

Trending NowMetal Zipper Stopper Repair KitDurable stoppers for various zippersMade from high-quality materials, these metal zipper stoppers ensure smooth operation and tight seals, perfect for repairs and outdoor gear.- Remove the old top/bottom stop with flush cutters; leave 3–4 mm of tape beyond the last tooth to hold thread or a crimp stop.

- Orient the slider so the channel opening faces the correct tooth profile (coils enter evenly; molded teeth seat in the channel groove).

- Insert one tape flank fully into its channel, then the opposite flank; push the slider slowly until it engages across the first 20–30 mm of teeth.

-

Temporary stabilization

- Before final stops, pinch the tape 10–12 mm past the intended stop location with a binder clip or small clamp to prevent tape creep during alignment.

- If teeth separate during feed, back the slider out 5–10 mm, realign the tapes by hand, then re-insert the slider.

-

Secure final stop

- Crimp-style metal stop: place the stop 6–8 mm from the slider when closed; crimp with flat-nose pliers using light, even pressure to avoid crushing tape.

- Sewn bar-tack option: use heavy nylon/polyester thread; make 6–10 tight parallel passes across the tape ~6 mm wide, then lock with 3–4 locking stitches. Stitch length ~1.5–2 mm per pass for maximum hold.

-

Lubrication for smooth travel

- Coil fasteners: use a thin silicone spray (1–2 short passes, then wipe) or paraffin rubbed along 10–15 cm and worked in with 6–10 slider cycles.

- Molded/vislon-style teeth: use paraffin or paraffin-impregnated cloth; avoid heavy oils that attract grit.

- Metal teeth: apply a light paraffin rub or a pencil graphite pass; avoid penetrating oils that stain fabric.

-

Initial operational test

- Cycle the slider fully open-to-closed 20 times at normal speed to seat teeth and evenly distribute lubricant.

- Observe for catching points; if a snag appears, inspect teeth with good light and use a small flat-head driver or dental pick to realign bent teeth, then re-cycle.

-

Load testing

- Static hang: close the fastener, attach a 10 kg (22 lb) weight to the closed area for 60 seconds; acceptable drift is ≤5 mm. If movement exceeds 5 mm, re-anchor the stop or repeat sewn bar-tack with extra passes.

- Dynamic test: load the bag or compartment with typical gear weight (5–12 kg depending on intended use) and operate the slider 10 times while loaded to check for separation under real-world stress.

- Final verification: after load tests, re-check stop integrity and retest 5 more open/close cycles; perform one full wash or wipe-down if lubricant residue is present.

-

If slider creeps or teeth misalign under load

- Tighten or re-crimp metal stops; for sewn anchors add 4–6 additional passes with heavy thread and lock off with a small backstitch.

- For persistent drift consider a locking-style slider (one-way detent) sized to the same pitch; install and re-test following the same sequence.

Keep records: mark the final stop location with a small dot of permanent marker and note the slider model and lubricant used for future maintenance checks.