Immediate recommendation: fold the excess shoulder webbing twice, pass the doubled section back through the ladder lock or tri-glide, then either secure with a stitched box-and-X or lock with a removable cam buckle. Aim for a visible tail of 5–8 cm beyond the anchor to allow adjustments; perform a static load check of 20–30 kg on each side to confirm zero slippage before regular use.

Tools and stitch specs: use a sewing awl or heavy-duty machine, a 2.0–3.0 mm upholstery needle and bonded nylon or polyester thread (approx. size #69 or 30 wt). Stitch a 25 mm × 25 mm box with an X across it and make 3–4 overlapping passes; backstitch 8–10 mm at entry/exit points. If hand-sewing, use a saddle stitch pattern and waxed thread for abrasion resistance.

Non-permanent alternatives: trap the extra webbing behind a tri-glide then clip a small cam buckle on the tail; use a silicone strap keeper plus an elastic loop to prevent flap-back. For a temporary field fix, run a thin cord through the folded bight and secure with a locking cord stop, or apply two UV-rated cable ties spaced 2–3 cm apart and cover with heat-shrink tubing to protect fabric and fingers.

Fit checks and durability notes: wear the pack for 20–30 minutes and re-check strap alignment and slippage; acceptable movement is under 5 mm under static load. Avoid exposing webbing to open flame; when fusing ends briefly use a lighter for 1–2 seconds at a distance of 5–10 mm to seal fray, then press molten tip flat with a metal tool. Reinspect stitches and fasteners after heavy use or every 3 months.

Refold and tuck excess strap into the buckle

Fold the excess webbing into neat 1–2 inch pleats and feed the tail back through the buckle’s rear slot so the folds sit flush against the main sling; this creates friction and removes slack immediately.

For tri-glide or ladder-lock hardware: pass the tail up through the lower slot, over the center bar, then down through the upper slot; fold the remaining tail twice toward the pack body and tuck the final edge under the first pass to lock. For side-release plastic fasteners with a rear channel, fold once lengthwise, then roll the folded tail and push it into the channel until it clicks under pressure.

Use these dimensional targets: for 1″ webbing allow 4–6″ of tail after folding (two 1–2″ pleats); for 1.5″–2″ webbing allow 6–8″ (two 2–3″ pleats). Aim for a final exposed tail of 1–2″ tucked; any more increases snag risk.

To keep the tuck stable during movement add a 1″ elastic loop, Velcro wrap, or a low-profile cable tie around the folded bundle; route the loop so it sits between the fold and the buckle body to avoid rubbing. Avoid bulky clamps that press on the shoulder area.

Quick diagnostics after tucking

If the webbing slips more than 1/2″ under 10 lbs of downward pull, increase pleat count or add a small friction loop. If the fold creates pressure points, redistribute by widening the first pleat to 2–3″.

| Webbing width | Folds recommended | Tail length after work | Retention aid |

|---|---|---|---|

| 1.0 inch (25 mm) | 2 | 4–6 inches | Elastic loop or Velcro |

| 1.5 inch (38 mm) | 2 | 6–7 inches | Velcro wrap |

| 2.0 inch (50 mm) | 2–3 | 6–8 inches | Low-profile cable tie |

For unrelated household maintenance tips refer to how to clean cat pee from wood floor.

Slider double-back method to lock webbing length

Thread the free webbing end through the adjuster in this sequence: under the inner bar (nearest the pack), over the center bar, then back under the outer bar so the tail runs parallel to the load-bearing portion – this creates a secure double-back grip.

Leave a tail of 3–5 cm for 25 mm (1″) webbing, 5–8 cm for 38 mm (1.5″) webbing; trim only if absolutely necessary and seal the end to prevent fray. Pull the main line tight while keeping the tail flat and untwisted, then seat the webbing so all bars are under even tension.

Verify hold by applying progressive load: hang 20–30 kg from the shoulder line or simulate normal wear and watch for slippage. If movement appears, add a second pass (triple-back) through the outer bar or place a small elastic keeper over the tail close to the slider to maintain tension.

For low-friction nylon or slippery webbing, secure the tail with three to five bar-tack stitches using bonded nylon thread or place a small zip-tie 5–8 mm from the slider and trim the excess tail flush. Orient the adjuster so the load-bearing lane presses the tail into the center bar; misorientation reduces bite and increases slip risk.

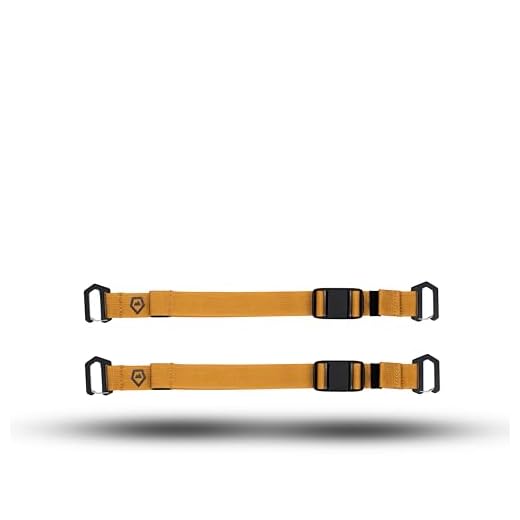

Loop excess through a D-ring and clip with a carabiner

Thread the loose webbing through the D-ring, fold it back to create a compact loop, pass the folded section over the ring so both layers sit flat against the main webbing, then snap a small locking carabiner through the double layer to lock position.

Use a screw-lock or twist-lock carabiner made of aluminum or stainless steel, 20–40 mm in length and rated at least 3 kN for durability; for everyday load management a 1.5–4 kN utility carabiner is acceptable but avoid unbranded thin clips. Choose a carabiner gate that closes perpendicular to the D-ring plane to reduce opening risk.

Leave 5–10 cm (2–4 in) of tail beyond the D-ring inside the loop to allow minor adjustments; if carrying heavier loads or frequent motion, form a second pass (double loop) and clip both layers for redundancy. For webbing narrower than 25 mm (1 in) use two small carabiners side-by-side or a single wider-gate model to prevent twisting.

Perform a pull test: apply steady tension of roughly 10–20 kg (22–44 lb) and inspect for slippage or gate rotation. If the carabiner rubs the D-ring or gate shifts, rotate the clip so the gate faces away from likely contact points and re-test. Tidy excess with a silicone band or a short piece of elastic threaded under the loop to prevent flapping.

Attach a removable elastic or Velcro keeper

Use a removable elastic loop (25–30 mm / 1–1.2 in wide; 10–15 cm / 4–6 in long) or a hook-and-loop keeper (20–25 mm / 3/4–1 in wide; 15–20 cm / 6–8 in long) to cinch excess webbing and keep it tidy near the adjustment point.

- Measure the loose length from the adjustment hardware to the tail end; choose a keeper length that leaves 2–5 cm / 1–2 in clearance past the gathered webbing for secure closure.

- Position the keeper 3–5 cm / 1–2 in below the adjustment junction so it won’t interfere with the buckle or slider movement.

- For elastic: slip the loop over the tail, stretch once to seat it, then join the ends with a sew-in snap or two bar-tacks (use polyester thread). Aim for 50–70% elastic stretch when closed so the keeper holds but can be pulled off by hand.

- For hook-and-loop: wrap the hook side around the webbing with 2–3 cm / 0.8–1.2 in overlap and press firmly. If the keeper is thin, add a single row of stitching across the overlap to prevent slippage during heavy use.

- Test with a 10–15 kg / 22–33 lb pull on the webbing; the keeper should stay put yet be removable quickly by hand for adjustment.

- Match keeper width to webbing: <15 mm use 12–15 mm keeper; 15–25 mm use 20–25 mm; 25–40 mm use 25–30 mm.

- Choose stainless or brass snaps for wet environments; low-profile black hardware reduces snagging.

- Bright-colored keepers make quick visual checks easier on multi-strap setups.

- Remove or fasten hook-and-loop before machine washing; hand-wash elastic at ≤40°C / 104°F.

- Carry one spare elastic and one spare hook-and-loop tie in a pocket for fast swaps on trail.

Add a cord lock or luggage buckle for quick temporary length reduction

Use a spring-loaded cord lock paired with a short length of 550 nylon cord threaded through the loose webbing tail and secured with a tight stopper knot for a fast, removable way to take up excess length.

Materials and sizing

Choose a barrel cord lock sized for the cord: small locks for 2–4 mm cord, medium for 4–6 mm. Recommended cord: 550 paracord (approx. 4 mm core; 550 lb rated) or 3 mm braided nylon for lighter use. Typical cord length per side: 12–20 cm to allow comfortable adjustment; buy 1 m to cover two sides and spares. For a hardware alternative use a 20–25 mm side‑release luggage buckle or a clip-in quick-release buckle that accepts a cord loop or thin webbing.

Step-by-step install

1) Move the loose webbing tail to the desired bearing point and note how much needs taking up. 2) Thread the cord through the webbing tail or through the adjustment ladder slot, then through the cord lock. 3) Tie a double overhand (or figure‑eight) stopper knot close to the cord lock, slide the knot inside the lock, and compress the lock to set the position. 4) Tug firmly to verify the knot and lock hold; if slippage occurs, add a second knot or use a slightly larger cord lock. 5) For a quick-release option, form a small cord loop through a luggage buckle, clip the buckle onto the webbing at the chosen point and snap closed; the buckle provides instant attachment and can be moved or removed with no sewing.

Notes on safety: cord locks and luggage buckles are for fit management and position-holding only – keep primary load adjustments in place for load-bearing and test on-ground before field use.

Route and store extra webbing inside the pack’s back panel

Feed excess webbing through the top rear access slot into the cavity behind the foam backer, then lay it flat and coil into 3–4 slim loops between the frame sheet and outer panel, anchoring the coil to an internal webbing tab.

Make each loop 1–1.5 cm thick so the total pack profile increases no more than 10–15 mm; if tail length exceeds 30 cm, increase to 4–6 loops. Leave a 5–8 cm free tail past the anchor so the harness can be re-tensioned while on the move.

For packs with a rigid framesheet: route the webbing behind the framesheet through the dedicated slot and place the coil against the rear of the sheet to keep load transfer intact. For frameless designs: tuck the loops between the lumbar foam and main lining or inside the hydration sleeve; avoid seating coils directly over the spine channel or ventilation channels to prevent pressure points.

Use existing sewn-in retention points (internal webbing loops, daisy chains or a velcro-backed patch) to secure the coil. If the interior lacks anchors, run a short length of thin cord through the coil and clip it to a gear loop or use a low-profile cord lock; avoid bulky fasteners that create hotspots against the back panel.

Close the back panel and load the pack with typical weight, then test for movement by shouldering and bending; if the coil shifts, re-route one loop through a different anchor or add a single internal stitch or discrete tie to lock position. For compact carry options and comparison ideas, see best luggage carry on with usb chargers.