Recommendation: Choose models constructed from 1680D ballistic nylon with TPU-coated panels and a reinforced vinyl base to maximize abrasion resistance and splash protection for daily urban use.

Primary shell textiles typically include 1680D ballistic nylon, 1000D Cordura and 600D polyester. The 1680D option offers the highest abrasion resistance and structure retention for heavy loads; 1000D provides a balance between weight and toughness; 600D reduces weight at the expense of long-term scuff resistance.

Laminates and surface finishes influence water performance and print fidelity: TPU-lamination maintains flexibility and excellent print clarity while offering water resistance; PVC coatings deliver glossy graphics and superior abrasion resistance but add stiffness; PU faux leather commonly serves as trim material for zipper garages and logo accents. Heat-sealed seams and water-resistant zippers improve wet-weather protection.

Hardware and internal components include YKK-brand zippers, Duraflex or metal buckles, reinforced nylon webbing (1″–1.5″) for straps, and bar-tack stitching at stress points. Back panels typically feature EVA or PE foam layered with 3D air mesh for comfort and airflow; reinforced bottoms often use double-layer fabric or welded vinyl for skateboard interaction and ground contact.

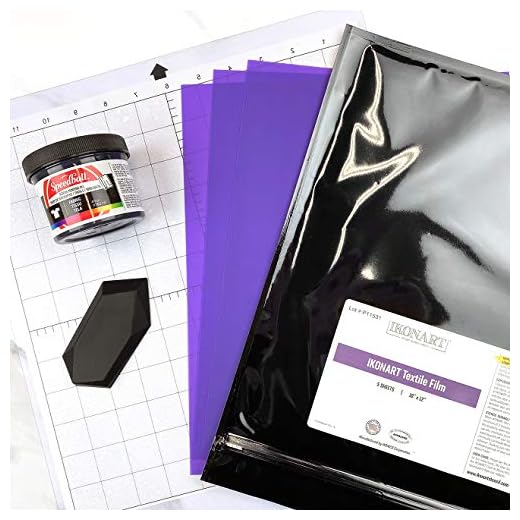

Graphic application methods vary: dye-sublimation and heat-transfer vinyl produce vibrant, long-lasting imagery on polyester substrates; screen printing and silicone/rubber patches appear on coated faces. Maintenance tips: spot-clean with mild detergent, avoid aggressive machine washing to preserve coatings and prints, restore TPU/PVC shine with appropriate care products, and check manufacturer warranty for hardware coverage.

Recommendation: pick 1680D ballistic nylon for maximum abrasion resistance and structure; choose 600D polyester for lighter weight, lower cost, and better print clarity; select PVC-coated fabric when daily wet-weather exposure or frequent cleaning is the priority.

600D polyester – best when weight, cost, and bright printed graphics matter. Expect moderate abrasion resistance, PU or TPU coatings for water resistance, and lower raw-material cost. Typical trade-offs: faster edge fraying under heavy abrasion, lower tensile strength than 1680D, but easier dye-sublimation and screen printing.

Performance comparison

| Property | 600D polyester | 1680D ballistic nylon | PVC-coated fabric |

|---|---|---|---|

| Denier (typical) | ~600D | ~1680D | varies (substrate + PVC layer), equivalent 600–1000D feel |

| Weight (approx.) | 200–300 g/m² | 650–900 g/m² | 500–1200 g/m² depending on coating thickness |

| Abrasion resistance | Moderate (good for daily city use, ~10–30k rubs depending on weave/coating) | High (excellent for heavy abrasion, >30k rubs typical) | High surface durability; coating resists scuffs but can crack at flex points over time |

| Water resistance | Good with PU/TPU coating; seams need taping | Good to very good with waterproof treatments; taped seams recommended | Very high when seams welded; inherently water-shedding surface |

| UV / colorfastness | Fades faster under sun unless UV-stable dyes/coatings used | Better UV resistance; maintains color and strength longer | Coating may yellow/crack over long UV exposure unless UV-stabilized |

| Print / graphic quality | Excellent for vibrant prints and detailed designs | Poorer for fine prints; usually limited to heat-transfer patches or woven labels | Decent for large graphics; printing on coating requires specific inks |

| Cleanability | Spot clean; avoid harsh solvents | Spot clean; more resistant to stains | Wipes clean easily; withstands detergents and pressure washing if seams sealed |

| Cost | Low–mid | Mid–high | Mid (depends on coating weight) |

Practical selection and care tips

For daily urban carry with graphic-heavy styling and light-to-moderate loads: choose 600D polyester with a quality PU/TPU coating; expect lighter overall kit and better printed detail, but plan for faster wear at abrasion points (base, corners). Reinforce with bar-tacked seams.

For heavy-use city gear that will rub against concrete, bike racks, or be loaded regularly: choose 1680D ballistic nylon; prioritize models with laminated backing, tape-reinforced seams, and abrasion-resistant base panels. Expect higher weight and price but much longer service life.

For daily exposure to rain, street grime, and frequent cleaning: choose PVC-coated fabric with welded seams or taped seam construction. Confirm UV-stabilization on the coating and inspect flex points for early cracking. Use mild detergents and avoid prolonged heat exposure.

How waterproofing works: PU lamination, PVC coating and seam sealing for rain resistance

For routine rain protection pick a PU‑laminated exterior with factory-applied seam tape and a hydrostatic head of at least 1,500–3,000 mm; for sustained exposure or near-submersion use a heavy PVC coating with welded seams and ratings above 10,000 mm.

-

PU lamination – construction and performance

- Method: a thin thermoplastic film (polyurethane or TPU) is laminated to the textile face using heat/pressure or solvent bonding; film thickness commonly 20–100 µm.

- Water resistance: laminated panels typically deliver 1,000–5,000 mm water column (hydrostatic head) depending on film thickness and adhesive quality.

- Behavior: retains fabric flexibility and lower weight, better packability; microporous PU variants can offer limited breathability but still block liquid water.

- Failure modes: delamination from repeated flex, abrasion or prolonged UV/heat; edge peeling often starts at zipper or seam interfaces.

- Care: wash with mild soap, avoid heat sources that can accelerate film breakdown, inspect edges and reapply liquid seam sealant if small leaks appear.

-

PVC coating – construction and performance

- Method: thicker plastisol or solid PVC is knife-coated or calendared onto the textile; coating gauges commonly 200–800 µm for heavy-duty applications.

- Water resistance: single-piece coated panels often exceed 10,000 mm water column; coating itself is impermeable to liquid water.

- Behavior: high abrasion and puncture resistance, easy to clean, heavier and stiffer than PU; may lose flexibility in sub‑zero temperatures and can be bulkier.

- Seaming: welded (RF or hot air) joints create continuous, stitch-free seals that match the coating’s impermeability.

- Care: wipe clean, avoid aggressive solvents that can soften PVC; inspect welds for cracks after heavy flexing.

-

Seam sealing techniques and practical recommendations

- Primary leak path: needle holes from stitching. Mitigation options include taped seams, welded seams or stitchless panel construction.

- Taped seams: thermoplastic tape (10–20 mm width typical) is heat-bonded over stitch lines; choose tape chemistry compatible with substrate (PU tape for PU laminate, PVC tape or welding for PVC).

- Welded seams: RF/hot-air welding fuses coating layers to create continuous seals; required for full waterproof performance with PVC coatings.

- Liquid sealants: silicone- or PU-based seam sealers fill stitch holes for field repairs; expect shorter service life than factory tape and reapplication after heavy wear.

- Overlap and edge details: minimum tape overlap over the stitch line of 8–12 mm reduces peel; reinforced seam paths in high-stress zones extend life.

-

Accessory and closure considerations

- Zippers: waterproof zippers (e.g., polyurethane-coated teeth or AquaGuard-style) reduce ingress but perform poorly without a storm flap.

- Flaps and roll‑tops: roll-top closures and external storm flaps add redundant protection for top-loading openings.

- Internal protection: for electronics use a sealed inner pouch or dry bag when risk of prolonged exposure exists.

-

Specifications, testing and maintenance

- Key tests: hydrostatic head (ISO 811, AATCC 127) gives objective water resistance numbers; seek manufacturer values rather than marketing claims.

- Simple field check: place a dry paper towel or tissue inside, spray or pour water on the exterior for several minutes, inspect for damp spots at seams and closures.

- Maintenance tips: remove seam tape that is delaminating and replace with compatible tape, reapply liquid sealer to small stitch leaks, avoid prolonged sun/heat to extend PU life.

Summary guidance: match laminate/coating type and seam method to exposure level – PU + taped seams for light-to-moderate rain with low weight and flexibility; PVC + welded seams for heavy rain, abrasive environments or where near-total water exclusion is required.

Hardware that matters: YKK zippers, metal vs plastic buckles and webbing strength ratings

Use YKK zippers for every major closure: specify YKK Vislon molded #10 for heavy-load mains, YKK #8 for regular mains, and YKK coil #5 for accessory pockets; choose YKK Aquaguard where water resistance is required; require locking sliders for laptop compartments and dual sliders with reinforced stops on main openings.

Zippers

Choose tooth type and size by load: #10 (≈10 mm tooth) for high-stress openings, #8 (≈8 mm) for everyday mains, #5 coil for pockets. Tape width guidance: 25–30 mm for #8–#10, 16–18 mm for #5. YKK Excella (metal) offers higher abrasion and shear resistance than coil for exposed zippers; Vislon (molded) tolerates grit and cleans easier. Specify UV-stable polyester tape and bartack/box-stitch reinforcement at stops and slider ends to prevent tape pull-through. For rain resistance pair Aquaguard zippers with an external storm flap or taped seams.

Buckles and webbing

POM (polyoxymethylene, aka acetal) side-release buckles suit chest straps and low-load closures; typical break loads fall in the 2–4 kN range. For load-bearing uses (hip belts, load-lifting points) use metal hardware: stainless steel, anodized aluminum or die-cast zinc ladder locks and side releases rated above 10 kN. Webbing width by function: 3/4″ for trim, 1″–1.25″ for shoulder straps on daily packs, 1.5″–2″ for padded hip belts. Minimum tensile recommendations: test shoulder-strap webbing to ≥2.5 kN and hip-belt webbing to ≥6 kN; attach webbing with box-stitch plus bar-tacks and a ≥25 mm folded overlap. For clip points and D-rings specify welded or cast metal; use stainless or brass where corrosion resistance matters.

best uv blocker umbrellas for recess duty

How graphics and finishes are applied and maintained: sublimation, screen printing, rubber appliqués

Recommendation: Use dye-sublimation on polyester panels for permanent, high-resolution prints; select plastisol screen inks for heavy-duty coated textiles when vibrant, opaque coverage is required; choose PVC or silicone rubber appliqués with perimeter stitching for badges that must withstand frequent abrasion and machine washing.

Sublimation: dye-sublimation injects gaseous dye into polyester fibers or polyester-coated substrates, producing prints that will not peel or crack under normal flex. Typical press settings: 380–400°F (193–204°C) for 30–60 seconds at medium pressure; settings vary by transfer paper and textile coating. Best substrate match: 100% polyester or polyester-faced laminates; poor results occur on nylon, untreated cotton, or heavy PVC coatings. Wash care: cold (≤30°C) or cool wash, mild non-ionic detergent, gentle cycle, line dry recommended; avoid chlorine bleach and dry cleaning solvents. Sunlight causes slow dye fade; use UV-stable inks or topcoat if long outdoor exposure expected.

Screen printing: selection of ink base dictates durability and hand. Plastisol inks sit on the surface, cure at ~320°F (160°C) and give high opacity on dark or coated textiles but may stiffen and eventually crack with extreme flex; water-based and discharge inks penetrate fibers, giving soft hand on natural fibers but deliver muted color on synthetics. For coated synthetic panels, use plastisol or specially formulated flexible inks plus a crosslinker; screen mesh 86–120T for bold solids, 160–230T for fine detail. Post-print curing with an industrial conveyor oven or heat press is mandatory for washfastness. Care: turn item inside out, cold wash, low-heat tumble or line dry; avoid high-heat ironing directly over printed areas and solvent-based spot cleaners that strip ink binders.

Rubber appliqués (PVC, silicone): molded patches usually 1–3 mm thick, attached by heat-welding, high-bond adhesives, stitching, or combinations. Heat-weld gives strongest bond to PVC-coated textiles when correct temperature/pressure applied; adhesive bonding needs industrial polyurethane or acrylic contact adhesives rated for flexible polymer-to-textile bonds. Stitching through the perimeter prevents edge lift during repeated washing. Maintenance: gentle hand wash or machine wash cold on gentle cycle; do not use acetone, petrol-derived solvents, or chlorine bleach; avoid prolonged tumble drying above 60°C and steam cleaning. Expect slight color shift or surface dulling after prolonged UV exposure; silicone holds color better than PVC in sunlight.

Protective finishes and repairs: a thin PU or water-based clear coat over screen prints increases abrasion and UV resistance but may add slight stiffness; apply at 10–25 μm wet film thickness and cure per product data. For small print damage, spot repair with compatible textile ink or heat-transfer patch; for delaminated appliqués, reattach using high-strength flexible adhesive plus a stitched perimeter. For long-term maintenance, store items away from direct sunlight and heat sources, follow cold-wash routines, and replace patched elements before adhesive failure leads to larger delamination.

FAQ:

What materials are most commonly used for the outer shell of Sprayground backpacks?

Sprayground typically uses synthetic textiles for the exterior: polyester and nylon in various deniers (600D, 900D and similar), often with a ripstop weave for tear resistance. Many designs use coated fabrics — PU or TPU laminates — to improve water resistance and surface smoothness for printing. Some limited editions include faux leather (PU) or PVC panels for a specific look. The choice of material depends on the model: lightweight styles favor nylon/polyester blends, while statement pieces may add coated or vinyl sections for graphic clarity and shine.

Are Sprayground backpacks waterproof or water-resistant, and how do the materials affect that?

Most models are described as water-resistant rather than fully waterproof. Coated polyester or nylon (PU/TPU finishes) repel light rain and splashes, and sealed zippers or storm flaps increase protection at the openings. Bags with PVC or vinyl panels offer higher water repellency on those surfaces, but seams, stitching and zipper areas remain potential entry points unless specifically sealed. For full submersion or heavy downpours, a dry bag or rain cover is safer. Treating fabric with a spray-on water repellent can raise resistance, but it won’t make a stitched textile completely waterproof.

How durable are Sprayground backpacks for daily use, and which components tend to wear first?

Durability varies by construction and materials. Heavy-duty denier polyester or nylon bodies combined with reinforced seams and bartack stitching at stress points usually hold up well under daily carrying, school use or commuting. Common wear areas are zipper pulls, bottom panels, strap attachment points and printed surfaces where abrasion occurs. Metal hardware or branded zippers (for example, YKK) last longer than cheap plastic zips, while plastic buckles can fail under repeated heavy strain. Padding in straps and back panels compresses over time, and vivid prints may show scuffing if the finish is soft. Picking models with reinforced bases, quality zippers and double stitching will extend service life.

Do Sprayground use recycled materials or environmentally friendlier alternatives in their backpacks?

Some recent releases and special runs feature recycled polyester or recycled PET fabrics, and a few pieces use lower-solvent printing methods to reduce emissions. However, many standard models still rely on conventional polyester, PU coatings and synthetic leather, which are not biodegradable. When a collection uses recycled content it is usually indicated in product descriptions. If reduced environmental footprint is a priority, look for specific notes about recycled fibers, water-based inks or minimal PVC use, and check for take-back or repair options offered by the brand or retailers.