Quick recommendation: for daily commuting with an average load of 6–10 kg expect the pack to remain fully functional for about 3–4 years. Light recreational use (a few outings per month) commonly yields 5–7 years. Intensive use–skate, heavy travel, sustained outdoor exposure–reduces serviceable time to 12–24 months.

Key factors that determine useful life are materials and hardware. Higher denier fabrics (600D–1680D polyester/nylon) and PU-coated textiles resist abrasion and water better than lightweight woven nylon (200–420D). Look for YKK or equivalent metal/coil zippers rated for thousands of cycles, reinforced bar-tacks at strap anchors, and double-stitched load paths; absence of these features typically halves real-world durability.

Maintenance schedule with concrete actions: spot-clean salt, sweat and dirt within 48 hours using mild detergent and a soft brush; full surface wash no more than once every 3–6 months depending on exposure (hand wash in lukewarm water, air dry away from direct sun). Reapply water-repellent spray (silicone or fluorine-free formulas such as Nikwax or Scotchgard alternatives) every 9–12 months or after heavy washing. Do not tumble dry or iron printed panels to avoid cracking of graphics.

Repair strategy and end-of-life indicators: replace zipper sliders and broken teeth (replacement sliders cost $3–10); reinforce frayed shoulder straps with heavy-duty polyester thread or a sewing shop; patch abrasion holes with Tenacious Tape or fabric glue for small cuts. Retire the pack when structural elements fail–seam separation at stress points, irreparable frame/board distortion, or shoulder straps that no longer accept padding–because those faults compromise load distribution and comfort.

Practical usage limits and preservation tips: keep carried weight under 10–12 kg for daily use, rotate between two packs when possible to halve wear cycles, store empty in a cool shaded area to prevent UV fade, avoid overstuffing main compartments and placing sharp objects directly against printed surfaces. Expect the manufacturer’s limited warranty to cover defects for roughly 12 months; consider third-party repair or local cobbler services to extend usable life beyond warranty coverage.

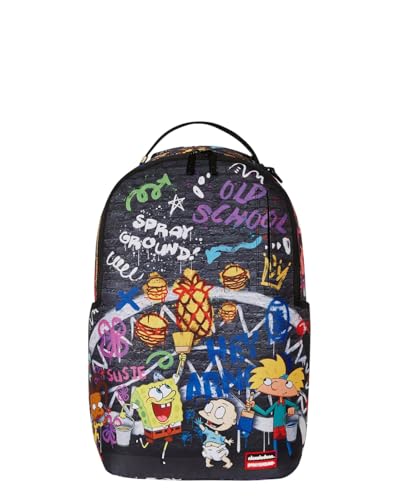

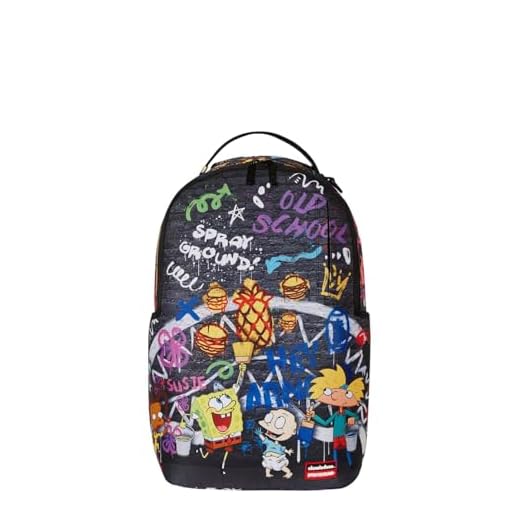

Recommended lifespan and maintenance for this streetwear label’s rucksack

Expect roughly 1–3 years with daily heavy use (commute or school, 8–12 kg loads), 3–6 years with regular use (several times per week, 3–7 kg), and 6–12+ years with occasional use (weekend or travel carry, <3 kg). These ranges assume normal wear without major accidents.

Material and construction benchmarks

1000D Cordura or ballistic nylon panels: retain structural integrity 5–10 years with moderate use. 600–900D polyester with PVC laminate: 3–6 years before coating shows microcracks or delamination if frequently exposed to heat/abrasion. PU-printed canvas designs: printed layer may craze after 2–4 years under heavy flexing. YKK or SBS zippers: functional 3–8 years depending on load and lubrication; sliders and stops are the most common failure points. Foam-padded straps and back panels: compression and foam breakdown typically visible after 2–5 years of daily use.

Maintenance schedule, load limits and repair guidance

Monthly: quick inspection of seams, zipper function and strap webbing. Quarterly: wipe with mild detergent, rinse, air-dry away from direct sun. Annually: treat exposed vinyl/PU prints with a vinyl protectant and lubricate zippers with silicone or beeswax. Recommended working load: keep daily carried weight under 8–12 kg to reduce stitching and strap failure; avoid single-side overloading. Small tears: use Tenacious Tape or vinyl patch immediately. Zipper replacements typically cost $20–60; strap/webbing replacement by a cobbler $10–30. Manufacturer defects are often covered for 12 months; third-party repairs extend usable service by several years when performed promptly.

Retire or permanently replace the item when structural seams split, major delamination occurs across load-bearing panels, shoulder straps lose padding and attachment integrity, or when repeated repairs become more costly than replacement.

Recommendation: choose full-grain leather for 5–10 years with quarterly conditioning, select heavy-gauge PVC-coated styles for 3–7 years if you avoid folding and heat, or pick high-denier polyester (600–1000D) for 4–12 years depending on reinforcement and care.

Material-specific averages and model notes

Leather – Full-grain leather models: light daily use 7–12 years; regular commuter use 5–8 years; heavy travel/streetwear 3–6 years. Bonded or PU leather: light 1–4 years; regular 1–3 years; heavy under 2 years. Typical failure points: edge cracking, creasing at stress zones, stitching pullout, hardware tarnish. Best for style-forward designs with repairable structure; avoid prolonged moisture.

PVC – Thick, laminated PVC/TPU-coated styles: light 5–8 years; regular 3–6 years; heavy 2–4 years. Thin or clear PVC: light 1–3 years; regular under 2 years; heavy often fails within a year due to cracking. Failure modes: coating delamination, seam splitting, plasticizer migration (stiffening or tackiness), decal peeling. Stronger models perform well if kept cool and not folded.

Polyester – High-denier (900–1000D/Cordura-type): light 8–12 years; regular 5–9 years; heavy 3–6 years. Mid/low-denier (600D and below): light 4–7 years; regular 2–5 years; heavy 1–3 years. Failure points: abrasion through base and corners, UV fade, zipper and strap wear. Best balance of weight, abrasion resistance and repairability for daily commuters and travelers.

| Material | Common model variants | Expected service (light / regular / heavy) | Main failure modes | Maintenance frequency |

|---|---|---|---|---|

| Full-grain leather | Structured fashion packs, reinforced bases | 7–12 yr / 5–8 yr / 3–6 yr | Edge cracking, stitching wear, scuffs | Condition every 3 months; clean & store dry |

| Bonded / PU leather | Budget leather-style models | 1–4 yr / 1–3 yr / <2 yr | Peeling, delamination, surface flaking | Wipe monthly; limit moisture and abrasion |

| Thick PVC / TPU laminated | Graphic-coated, glossy finishes | 5–8 yr / 3–6 yr / 2–4 yr | Coating cracks, seam failure, decal lift | Wipe weekly; avoid heat/creases; restorer yearly |

| Thin / clear PVC | Transparent panels, novelty pieces | 1–3 yr / <2 yr / <1 yr | Rapid cracking, scratches, yellowing | Gentle cleaning; store flat; avoid sun |

| High-denier polyester (900–1000D) | Reinforced commuter / travel models | 8–12 yr / 5–9 yr / 3–6 yr | Abrasion at seams, zipper failure | Spot clean monthly; DWR re-treatment twice yearly |

| Mid/low-denier polyester (600D and below) | Lightweight everyday styles | 4–7 yr / 2–5 yr / 1–3 yr | Fabric abrasion, UV fade, strap fray | Spot clean monthly; reinforce high-stress seams |

Practical choices to extend useful service

For heavy users pick high-denier textile with a reinforced base and replaceable zippers; for travel choose leather only if you commit to quarterly conditioning and seam attention. For graphic-coated designs prioritize rigid, thick-laminate PVC and avoid folding or storing in hot cars. Apply water-repellent treatments to polyester twice a year, lubricate zippers every 6–12 months, and repair loose stitching immediately to add multiple seasons of use. Typical manufacturer warranties run 1–2 years; consider third-party repairs for leather to extend service beyond warranty periods.

Daily use, travel and storage: concrete steps to extend service life of these designer packs

Recommendation: Rotate between two bags for daily duty, keep loaded weight under 4–6 kg (9–13 lb) for routine commuting, use a padded cover and place the bag in carry-on when flying, store empty in a breathable dust bag with silica gel at 18–22°C and 30–50% relative humidity.

Daily wear: carrying 4–6 kg during a typical 8–10 hour day produces visible wear on high-friction points (strap anchors, base corners, zipper tape) after roughly 18–30 months of uninterrupted use. Increasing that load to 7–10 kg raises abrasion and seam stress so that issues (frayed webbing, stitching failure, zipper separation) commonly appear within 6–12 months. Rotating two bags reduces continuous stress cycles by about 50%, translating to an approximate doubling of useful service time for fabric and hardware.

Commuting conditions that accelerate damage: repeated shoulder abrasion from coat hardware, constant contact with rough surfaces (concrete, subway floors), and carrying unpadded electronics without internal separation. Mitigations: add a thin laptop sleeve, apply edge-protective tape to the base corners, and avoid loading loose metal objects into exterior pockets.

Air and ground travel: checked handling multiplies surface scuffs and hardware impacts; expect scuffing and zipper dents after 10–25 checked segments. Carry-on use keeps exterior finishes intact but stresses interior seams from overpacking. For frequent travelers (50+ flights/year) use a hard travel box or padded wrap when checking the bag; for carry-on, compress contents with packing cubes to prevent internal shifting that strains seams. Remove detachable straps and secure loose buckles before transit.

Cleaning and maintenance schedule: wipe PVC or coated surfaces after each trip; perform a fuller clean (mild soap, soft brush) every 6–8 weeks with moderate use, or every 3–4 weeks for heavy daily use. Treat leather accents with a dedicated conditioner twice per year; avoid machine washing fabric panels – hand wash and air dry only. Lubricate zippers with a dry silicone lubricant every 3 months or after exposure to saltwater.

Storage practices that affect degradation: prolonged compression (vacuum-packed or under heavy objects for months) deforms foam shoulder pads and crushes internal structure; avoid stacking items atop stored bags. High humidity (>60% RH) encourages mold and glue failure within months in warm climates; use silica gel packs and a ventilated storage bag. Sunlight exposure for more than 1–2 hours daily fades prints and weakens dyed coatings – store away from windows.

Damage thresholds and quick checks: replace webbing when fray exceeds 10% of original width; repair seams once any stitch break appears rather than waiting for progressive failure; address surface cuts or punctures within 48–72 hours to prevent tearing under load. A simple weekly inspection of straps, zipper alignment, and lacquer finishes prevents small problems from becoming structural failures.

Actionable checklist: rotate bags weekly; limit daily loads to 4–6 kg; carry fragile items in padded sleeves; use padded cover for checked travel; clean major spills immediately and do a full clean monthly for heavy use; condition leather twice yearly; store empty, upright, breathable, with silica gel; repair stitching at first sign of failure.

Simple cleaning and maintenance steps that add years to a branded streetwear pack

Wipe exterior panels with a solution of 1 teaspoon mild, pH-neutral detergent per 1 liter (0.26 gal) of cool water every 2–4 weeks; deep clean by hand every 3–6 months depending on wear and exposure.

For coated PVC panels: use a soft microfiber cloth and the detergent mix above; rub along the grain, not against it. For stubborn ink or oil spots, test 70% isopropyl alcohol on an inconspicuous area for 10 seconds, then rinse immediately with cool water. Never use bleach, acetone, or concentrated solvents; do not iron or expose coated panels to temperatures above 45°C (113°F).

For genuine leather trim: spot-clean with a damp cloth and a dedicated leather cleaner (apply cleaner to the cloth, not directly to the leather). Condition leather every 3 months with a neutral leather conditioner (0.5–1 mL per 10 cm² of treated area). Keep leather panels out of direct sunlight during drying and store at room temperature to prevent drying cracks.

For woven polyester and nylon: hand soak in cool to lukewarm water (max 30°C / 86°F) for 10–15 minutes, agitate gently, rinse thoroughly, and air dry stuffed with a towel to retain shape. Machine washing risks delamination of laminated panels and should be avoided unless manufacturer tag explicitly permits a gentle cycle inside a laundry bag.

Zippers and hardware care: brush sand and grit from teeth with a soft nylon brush after outdoor use. Lubricate metal and coil zippers every 2–3 months or after rain with a silicone-based zipper lubricant or a thin coat of paraffin; do not use oil-based lubricants on coated webbing. For metal fittings exposed to salt, rinse with fresh water and dry immediately; remove surface rust with a non-abrasive metal polish and protect with a micro-thin film of machine oil applied sparingly to moving parts.

Stitching and small rips: repair loose stitches within 48–72 hours using heavy-duty bonded nylon thread and a curved upholstery needle, or apply a 3–4 cm Tenacious Tape patch on the interior for fast reinforcement. Replace frayed webbing before connector failure; melt nylon frays cautiously with a lighter and press flat with a metal object.

Load management and everyday habits: keep regular carried weight under 10 kg (22 lb) for daily use – occasional peaks to 15 kg acceptable but will accelerate wear at seams and base. Empty contents at day’s end, air interior for 10–20 minutes to reduce moisture buildup, and use silica gel packets in humid climates.

Storage best practices: store in a breathable cotton dust bag or pillowcase in a cool, dry place (10–25°C / 50–77°F, relative humidity 40–60%). Avoid plastic bins that trap moisture. For rainy seasons use a dedicated rain cover or umbrella (best umbrella schools in tennessee) to prevent repeated water saturation which weakens adhesives and stitching.

Maintenance schedule at a glance: weekly – quick wipe and interior airing; monthly – full exterior wipe and zipper brush; every 3 months – leather conditioning and hardware inspection; every 6–12 months – full hand wash and seam reinforcement as needed. Address stains and mechanical issues immediately to prevent progressive damage.

Common failure points and spotting when a pack needs repair or replacement

Inspect zippers, seams, straps and structural panels monthly and before trips; repair small defects within 2–4 weeks, replace the bag when load-bearing parts fail or repair cost exceeds roughly 50% of current retail value.

-

Zippers

- Signs: skipped teeth (3+ consecutive), slider splitting open under a light one‑hand pull (~5 kg / 11 lb), teeth bent or missing, stops torn off.

- Repair vs replace: replace slider or stops for isolated failures; replace whole zipper if more than 20% of teeth are damaged or if repeated failures occur on main compartment zipper.

-

Seams and stitching

- Signs: loose threads longer than 5 mm, seam gap >3 mm, stitch loss over >10% of a seam length, seam tape peeling on taped seams.

- Repair vs replace: restitching is effective for up to ~20–30% of seam length; replace the bag if multiple load-bearing seams fail or if repairs would alter structural integrity.

-

Shoulder straps and hardware

- Signs: foam padding compressed to less than 50% of original thickness (for example, from 20 mm to <10 mm), webbing fray wider than 5 mm, buckles that crack or fail under normal closure, D‑rings pulled out.

- Repair vs replace: swap buckles/D‑rings and re‑stitch straps for isolated damage; replace the bag if straps are integral and foam or webbing failure affects load distribution across both sides.

-

Exterior fabric and coating

- Polyester/canvas: holes >5 mm or fabric worn through; abrasion across >20% of a panel reduces service life.

- PVC/TPU coating: blistering bubbles ≥10 mm, edge peeling >20 mm, or delamination covering >30% of a main panel indicates replacement; small blisters can sometimes be glued and sealed.

- Leather trims: surface scuffing is repairable; cracks deeper than ~1 mm or flaking that affects >30% of trim area usually means replacement of that component or the whole bag.

-

Internal lining and foam

- Signs: main compartment lining tears >5 cm, persistent foam breakdown (crumbly or binding), or padding compressed by >70% of original thickness.

- Repair vs replace: relining is possible for high‑end bags; if interior foam or structure is fused with shell and failing, replacement is often more economical.

-

Water resistance and seams

- Quick test: pour 240 ml (1 cup) of water over a taped seam; if moisture appears inside within 30 seconds, waterproofing is compromised.

- Repair vs replace: re‑seal seams with seam sealer or replace seam tape for localized failures; replace the bag if waterproofing across multiple panels is lost or coating delaminates widely.

-

Mold, odor and contamination

- Signs: persistent musty odor after cleaning and 72 hours of drying, visible mold embedded in foam or lining, staining that won’t bleach out.

- Repair vs replace: surface mold can be cleaned and treated; replace the bag if mold has penetrated padding or adhesive layers, or if odor persists after two rounds of professional cleaning.

-

Structural frame and shape

- Signs: warped internal frame, permanently collapsed pockets, major misalignment of zippers caused by frame deformation.

- Repair vs replace: minor frame fixes available for framed daypacks; if the shell has lost shape across main load panels, replacement is recommended.

Decision checkpoints (use these thresholds to choose repair vs replacement):

- Single non‑load zipper or small seam failure: repair if cost <15% of retail price.

- Multiple load‑bearing failures (both straps, main seam and frame): replace.

- Widespread coating delamination, leather flaking over >30% of surface, or foam compression >70%: replace.

- Repair cost >50% of a new unit’s price: replace.

Common repair actions and realistic lifespan extensions:

- Replace sliders/stops: 6–12 months extension for isolated zipper faults.

- Professional restitching and strap replacement: 1–3 years depending on fabric wear.

- Re‑seal seams and apply a new waterproof coating: up to 2 years if underlying fabric intact.

- Leather conditioning and edge repair: can add several seasons if cracks are surface‑level only.

If heavy travel or regular airport use causes repeated structural failure, consider wheeled alternatives for heavier loads such as a best rolling backpack carry on to reduce stress on shoulder straps and seams.